Home Site Map - Techniques - Interior Infrastructure -

Radiant Heating

![]() Use your domestic water heater to also warm your feet

Use your domestic water heater to also warm your feet

Heating the floors can be done either with an electrical heating mat or using hot water carried by PEX pipes. For larger areas, hot water radiant heating is preferred and is my choice.

Concrete floors, ie the concrete structure, have in the past been used for radiant heat because of their high thermal mass. It does however take a great deal of energy to bring concrete structure up to temperature from a cold start, so embedding in the concrete structure is not the best way of doing it. A much better bet is to use what's called a low-mass radiant floor. With a low-mass radiant floor, some of the heat is fairly immediately used to heat the air of the room and some of it goes towards gradually heating the concrete structure of the house.

Martin Holladay says... "Although in-floor radiant systems are a good way to heat a poorly insulated house, they are overkill and a waste of money in a small, tight house. If your goal is simplicity, there’s no reason to invest $12,000 or more on a boiler, one or more circulators, and hundreds of feet of tubing just to supply 15,000 Btu/hour on the coldest day of the year."

With a highly insulated air tight house you don't need a big boiler and you can get away with using a regular low cost hot water heater.

In addition to the true benefits and comforts of radiant floor heating, having radiant heating in your home is a trendy sales feature and as such will increase the value of your home.

My Radiant Heating

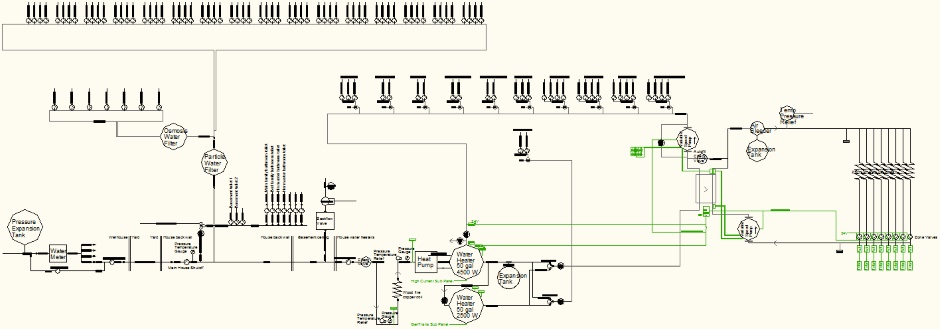

My design of radiant heating system is integral with the house hot water system which makes it a less expensive capital outlay and more efficient. The only limitation is that it can only do about 15,000 BTU/hr, but if you have a well insulated air tight house then that's plenty. One watt is 3.412 BTU/hr, so 15,000 BTU/hr is provided by about 4,500 W of resistance heating (or the equivalent done with a heat pump).

Domestic hot water isolated from radiant heating

The best design for a radiant heating system is closed loop and a house hot water system is inherently open loop. Domestic hot water is potable water and the water is oxygenated. Radiant heating hot water can become stale and may grow legionnaire's disease, and it needs to be free from oxygen so as not to cause problems with cast iron pumps. The bottom line is that the potable hot water needs to be isolated from the radiant heating water. The isolation is done with a heat exchanger. To use a heat exchanger it is necessary to have a pump on the source side to circulate potable hot water through the heat exchanger.

Source circulation pump

Given that it is necessary to have a pump to circulate the domestic hot water through the heat exchanger, you can also use it to circulate hot water past all the hot water faucets in the house. This avoids there being any sections of pipe with warm water that could grow legionnaire's disease, and it means there is always hot water delivered to the faucet without the normal wait time for the faucet to get hot. The loop around the house is done with 3/4" PEX and it has an insulated jacket on the PEX to avoid unwanted heat loss in the summer months.

A variable speed stainless steel pump is used to circulate the domestic potable hot water. The speed is determined by the temperature that you are trying to achieve on the radiant heating side of the heat exchanger. That means the circulation speed around the house hot water loop varies, but in practice it is always moving sufficiently. The source circulation pump has a minimum speed (when the pump is on) so it works even if the radiant heating zones are all off.

Zone actuators and radiant pump speed

For the radiant heating system, the use of thermostat controlled 4 wire valve actuators on the return side of the manifold, together with a temperature difference sensing variable speed pump, provides the system control. 4-wire valve actuators have an isolated micro-switch inside that can be used to form a logic "OR" function such that the radiant heating pump only operates when at least one PEX loop is open. As well as being efficient on pump electricity usage, this also avoids needing a Pressure Regulating Bypass Valve. Inside a variable speed pump is electronics that senses the temperature difference between the water temperature into the supply manifold and the water coming back on the return manifold. The smaller the temperature difference, the slower the pump operates. Thus the pump keeps the system operating at its most efficient point and the pump uses less electricity.

Hot water heating shared

The hot water for both the radiant heating and the house hot water faucets, showers, and baths comes from a regular commodity 50 gallon hot water heater such as can be purchased from Lowes for about $350. Because there is only one hot water tank, if you decide to optionally purchase a heat pump to efficiently harvest heat from for example a wood burning fire then you get the heat pump benefit for both your house hot water and your radiant heating. The same is true when using a copper tube coil to pre-heat water using heat from a wood fire chimney.

Hot water heater capacity

The hot water boiler typically will have a 4,500W electrical resistance heating element. This gives just over 15,000 BTU/hr. When taking this amount of heat for your radiant heating, the hot water heater will still be able to keep the 50 gallons at a temperature of 135 degrees F. If you take out say 25 gallons for a deep soaker bath then there will be a half hour recovery time to get the full 50 gallons back to 135 degrees, but in practice you will be unlikely to notice any difference in your radiant heating performance.

Humans want variable radiant water temperature

On warmer days it provides more human comfort to use a lower water temperature through the radiant heating pipes. It is good to measure the outside air temperature and automatically adjust the radiant water temperature accordingly. The outside temperature sensor should ideally be on the outside north wall of the house under the eves to keep it out of the sun.

Radiant heat temperature control

The best radiant water temperature (deg F) (up to a sensible

maximum of 130 - 135 deg F) for a given outside

temperature (deg F) is...

Outside

Radiant Source

< 19 130

(or Max)

20

- 30 120

31 -

41 110

42

- 52 100

53 -

63 90

64 -

74 80

> 75 Off

The hot water tank temperature will always be set to a constant 135 degrees F. The radiant heating source temperature can be varied by varying the speed of the source circulation pump. If the water speed through the source side of the heat exchanger is slow then not much heat will get through the heat exchanger to the radiant heating side.

Source pump on/off

The source circulation pump is turned on (via its "heat demand" 24V input) when any radiant heating zone manifold actuator micro-switch is on (micro-switches connected in parallel to do an OR function) or when the temperature at the end of the main house hot water loop drops below a specified temperature. It turns off if the temperature at half way up the water tank drops below a specified temperature (eg 120 deg F). The tank temperature switch is to ensure that there is always plenty of hot water available for a bath. The heating relay output from the temperature switch on the water heater is used to ground the "heat demand" input on the source circulation pump (with a resistor in the enable line). It might be thought to be nice to gradually reduce the speed of the source circulation pump when getting low on hot water in the tank, but the total shutdown of the heating system won't last long and the hot water tank will soon recover. The thermal mass of the house will smooth out the short time when the heating is off.

Source pump speed control

Once the source pump is turned on, the speed it operates at is determined by the target temperature it is trying to get the radiant water source temperature to on the radiant heating side of the heat exchanger. Intelligent variable speed pumps such as the Taco model shown below operate on a delta-T principle. The delta-T is selectable on the pump and can be set to eg 10 deg F. Typically there is a temperature sensor on the source side of the radiant heating zone manifold and another temperature sensor on the return side of the manifold. They pump at whatever speed is necessary to ensure that the return side is 10 degrees less than the source side. If the source is 110 def F and the return side is 90 deg F then the pump will speed up to get the return side to be 100 degrees. If the source temperature sensor is replaced with an electrical resistor to mimic the temperature being 110 deg F then the pump will go as fast as necessary to get the temperature monitored by the remaining temperature sensor to be 100 deg F. In my source circulation application, the temperature sensor that would normally be on the return side of the manifold is attached to the source side of the radiant heating zone manifold. The other temperature sensing input (that would normally have been on the source side of the zone manifold) is connected to a switchable set of resistors. If the variable speed intelligent pump is set to keep the delta-T at 10 degrees and the source temperature sensor input is being told that it is 110 degrees then the pump will run fast enough to get the radiant heating source temperature to be 100 degrees. That means the switched resistor array on the source pump needs to have resistor values that request 10 degrees higher than you will actually get. The resistor ohm values will vary depending on the pump used but here are the values for the Taco pump for different deg F...

Req Temp Calc ohms Adjusted ohms

Outside Temp Action

130 (Max) 3,050

2,490

< 19 Fixed

resistor

120

3,760

3,050

20 - 30 Unit 1 at 20 F opens heat relay

110

4,665

3,760

31 - 41 Unit 2 at 31 F opens heat relay

100

5,828

4,665

42 - 52 Unit 3 at 42 F opens heat relay

90

7,334

5,828

53 - 63 Unit 4 at 53 F opens heat relay

80

9,299

7,334

64 - 74 Unit 5 at 64 F opens heat relay

Off

(11,883) (9,299)

>75

Also shown in the above table is the corresponding outside temperature and the action that is taken at different outside temperatures.

Multiple Temperature Switch units appropriately set with the required outside temperature (20, 31, 42, 53, 64) can be used to un-switch resistors in parallel to achieve the required resistance values. It does require five sensors to be housed outside as each temperature switching unit requires its own sensor. There is no need to explicitly turn off the source pump when the outside temperature is high (>75) because the zone thermostats will turn off the zones which will cause the pumps to turn off. The set of temperature switches will be on the basement back wall with the sensors under the north deck. It is ok to have a long wire between the resistor bank and the pump because it is typical to have a long distance between a temperature sensor and the pump electronics.

Radiant heating pump on/off/speed

The radiant heating pump is turned on (via its "heat demand" 24V input) when any radiant heating zone manifold actuator micro-switch is on (micro-switches connected in parallel to do an OR function). A 24V relay is used to provide the difference between the signal that enables the source pump relative to the signal that enables the radiant heating pump.

When the pump is on, it decides its speed by comparing the return manifold temperature with the source manifold temperature in order to keep the delta T to a 20 deg F difference.

Calculations

Use 10 deg F delta-T

On the radiant heating side it is good to set the delta-T to be 20 degrees F. Some people prefer a delta-T of 10 degrees F but that means the pump has to work faster (using more electricity and making more noise). Also if the water in the pipes it moving fast you may hear it.

Radiant water pressure

You can use a high pressure eg 50-80psi for the radiant loop, but you only need greater than 10psi to do a 23 foot head (the pump is only 17' head). An auto-fill check valve between the domestic hot water and the radiant heating closed system is used to set the PSI for the radiant and to provide any top-up water that might be required. My choice is to set it to 15 psi for normal use, but it's convenient to be able to set it to a higher pressure for pressure testing the system.

Required GPM

To calculate the required GPM, use... GPM = 0.002*BTU/(Temperature Drop, F). Since most radiant heating systems utilize a 20F temperature drop, the formula becomes: 1 GPM = 10,000 BTU/hr. In my case I want 15,000 Btu/hr so that's 1.5 GPM. As there are 8 zones, that means about 0.2 GPM in each zone.

Pump head

The calculation of required pump "head" has nothing to do with the vertical lift height in a closed loop system because the same weight of water that is lifted is balanced by the water returning down from that height. The head calculation is all about the resistance to flow of the PEX pipe. You need to look at the spec for the particular brand of PEX pipe, but here's an example calculation. One foot of 1/2" PEX tubing at 0.2 GPM flow rate would be something like 0.007 ft of head, so 250' of PEX would be a head of 1.75 feet per zone. Since PEX zones are in parallel, the total system pressure drop is the same as the pressure drop per zone, so the total head that the pump has to handle is 1.75 feet.

Zone design

It is not practical or desirable to put a thermostat (or separate loop) in every room. Sleeping areas and bathrooms that are joined are generally controlled by one thermostat (ie one zone loop). Areas that are open to each other are generally controlled by one thermostat (one zone loop). It is typical to have about two or three thermostats (two or three zone loops) per floor. Basically a zone size comes down to the area covered by 250 - 300 feet of PEX tubing.

You don't have to make the length of PEX the same for each zone as you can adjust the shutoff valves on the radiant manifold to balance things, but even so it is still good to keep the zone PEX lengths something close to the same size.

Areas of a zone that you want hottest should be closest to the hot water source end of the PEX run.

Conventional wisdom says do not put piping in the floor within 12" of the wall. Do not put piping under areas you want cool such as a pantry, refrigerators, and freezers. Put it mainly where people will have their feet.

For cold areas you can use a greater density of pipe or do a double loop.

The area that constitutes a zone is likely to be mainly determined by the area covered by 250 - 300 foot of PEX pipe. When planning the routing it is best to think in terms of what areas of the house are in constant use (by just 2 people) and what areas are just used on special occasions (whole family visiting). If there are any apartments then it is good to make each apartment a separate loop so they can be shutdown when not in use.

In my house I need 9 zones (Basement 2, Main level 4, Bedroom level 3).

PEX in wooden sub-floor above concrete

Use a wooden sub-floor (on every floor) with the radiant pipes positioned between the wood support lumber. That way you get some instant zone specific heating with a secondary effect that the concrete underneath will gradually warm up to provide longer term heating.

Using plastic bodied staples to attach the PEX to the side of the glued 2x4 support lumber is faster than cutting grooves in wood.

The PEX pipes do not need to be directly in contact with the top wood flooring. Lay the PEX in the 8.5" gaps between the 1 foot on center 2x4 support lumber. Use a staple every 2 or 3 feet. Don't staple the PEX pipe bends as you want to allow for expansion.

Another nice thing about a wooden sub-floor is that it provides a place to run wiring.

The 2x4s are 1 foot on center and under them are shims to take out any unlevelness in the concrete slab.

If you want to you could reduce the concrete heating rate relative to the more immediate air heating by using foil or mylar insulation on the surface of the concrete, but personally I do not do this.

If found necessary, use plastic electrical conduit to protect the PEX tubing as needed, eg tight bends in and out of the floor.

When the PEX piping is not embedded in concrete there is the possibility that you will hear the water flowing. Some PEX pipe is better than others at reducing flow noise. It is also good to keep the water flow rate to a minimum by using a 20 degree F delta-T rather than 10 deg F.

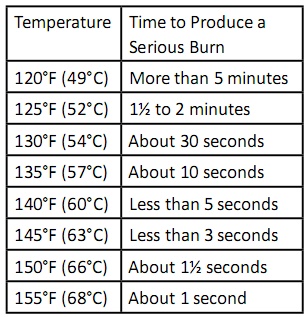

Legionnaires' disease

The minimum temperature to prevent Legionella Bacteria growth is 122°F. Above 122°F and up to 131°F, Legionella bacteria survives, but will not multiply. At 131°F, it takes about 5 to 6 hours for the bacteria to die. At 140°F, the bacteria dies in about 32 minutes. At 151°F, the bacteria dies instantly. The recommended minimum disinfection temperature is a few degrees above 151°F, which is 158°F for about 5 minutes. To prevent bacteria growth, a safety factor of a couple of degrees would require a minimum of 124°F at the coolest spot in the hot water distribution system. The lowest temperature of hot water in a circulated hot water distribution system is always in the hot water return piping right before it connects back to the water heater.

The bottom line is that there is a high probability of getting Legionnaire bacteria in radiant heating pipes. Because of this it is necessary to isolate the radiant heating hot water from the domestic hot water using a heat exchanger.

Water temperature

Officially the best bath temperature is supposed to be 112 degrees F. Personally I prefer it a bit hotter.

The water temperature in the water boiler can be a lot higher than the hot water from the faucets by using mixing valves in the hot water distribution system.

Making Hot Water

Water heater

A domestic water heater only can do about 4500W which is 15354 BTU/hr . (1W = 3.412141633 BTU/hr). This is likely to be enough if your house is highly insulated and air tight. Using a regular domestic water heater is a lot less expensive as it is a commodity item. You will be sharing the water heater between your radiant heating system and your house domestic hot water (for faucets, showers, baths, washing machine, and dishwasher).

The water heater will want to be set at about 135 degrees F.

A useful feature on the Whirlpool tank is that it has a port a little way down from the top that is designed to be used for the tank's temperature/pressure relief valve. You can use this port to return not fully hot water to the tank from the radiant heating heat exchanger and house hot water circulation loop without upsetting the water temperature stratification within the tank.

It is best to have the water tank mounted higher than a wood fire copper coil heat exchanger so even without the pumped water movement you still potentially get some slight hot water circulation.

Air source heat pump

It is best (but optional) to have a heat pump attached to the water heater.

An air source heat pump extracts heat from the air and uses it to make hot water in an adjoining water tank with an efficiency of over 200%. It works particularly well if the air is hot, eg if the heat pump is in a room with a wood burning fire.

Wood fire chimney water heat exchanger

If you have a wood fire, pre-heating cold water going to the house hot water heater using a water coil at the base of the chimney is a reasonable idea.

It is best to avoid messing with the firebox on your EPA approved fire as this can be dangerous. Modifying your firebox can also cause problems with your insurance. You can however implement a DIY water heat exchanger round the chimney using a coil of copper pipe. This is mainly just capturing heat that would be otherwise radiated into the room, although you are reducing the chimney temperature and therefore reducing fire combustion operation at bit, so you only want to do it sparingly.

While a good idea, it is not however quite as good as you might think. If hot water is not being used by a faucet then the water will be stationary in the water coil and will get very hot. If hot water is being used fast by a faucet then the water through the coil will not have enough time to get hot so you will not get much benefit. Despite the limited functionality it is still my choice to do it.

Copper pipe coil heat exchanger

Use 3/4" soft copper tube. Use about 50 feet. Use "refrigeration" type copper tubing as it is thick and soft.

Cold water input is into the bottom of the coil, and output is from the top.

It is good to use thermal mass decoupling. Rather than putting the coil of copper pipe directly in contact with the chimney, it is better to somewhat decouple it using brick or stone masonry. This reduces the chance of the water boiling in the pipe coil. It also smoothes out the heat over a longer time if the fire burn is intermittent. It also should ensure that no fire inspector or insurance agent will have a problem with it. Brick or stone will also look nice.

Combination pressure temperature relief valves

You MUST use pressure/temperature relief valves on the inlet and/or the outlet tubing. It is best to have two pressure relief valves (one at each end of the coil) in case one fails. Combined pressure/temperature relief valves are preferred because they will release long before the water turns to steam and increases the system pressure. Pressure relief valves let out water so this needs to go to a drain pan and drain.

Pressure Temperature Relief Valve

Pressure Temperature Relief Valve

Pressure gauges

Use pressure gauges on both the coil input and coil output to monitor the performance and safety of the system.

Temperature measuring

Use a temperature display at the top and bottom of the water coil.

Radiant heat source

Heat exchanger

This is what provides isolation between the potable domestic hot water and the water in the radiant heating closed system. Heat is transferred from the domestic hot water to the radiant heating water.

It is possible to use a less efficient heat exchanger to save money and it will work ok, but I prefer to over engineer it and go for a more efficient one. The better the heat exchanger, the slower the water circulation on the source side needs to be.

Source variable speed circulation pump

This moves hot water from the top of the hot water tank and returns it to the hot water tank. As the returning water will still be pretty hot it can be fed back into the hot water tank near the top.

On the source side the water is oxygenated so it is necessary to use a stainless steel pump.

Variable speed

circulator pump

Variable speed

circulator pump

The pump speed depends on the differential between the two temperature sensors (up to a max differential of 50 deg F). The "return" sensor goes on the output of the heat exchanger (that connects to the source side of the radiant heating manifold). The lower temperature sensor is replaced by a relay switchable resistor bank to set the required radiant heating temperature.

In practice to allow for a delta-T of 10 degrees the actual resistances used should adjust by one notch (see above). Set the range dial to position 2 to tell the pump to use a 10 degree delta-T.

If the output temperature is at or higher than the target temperature then the pump will (depending on the set mode) either turn off or go at minimum speed. I set it to minimum speed mode so that water is always circulating through the house hot water loop past the faucets.

The pump can be turned on or off using 24V to the "heat demand" input on the pump. A jumper can be used to set the pump to continuous operation, but I remove the jumper.

If the radiant heating system is off (eg in the summer) (no zone micro-switches closed) then the source circulation pump will get turned off. Instead a temperature switch is used to operate the pump when the temperature in the house hot water loop return pipe has dropped to below a set temperature. The relay in the temperature switch is wired in parallel with the zone actuator micro-switches to make it operate like an additional zone.

The pump should be orientated to pump vertically up to keep air bubbles out of it.

The pump is also used to circulate the domestic hot water (see that section).

Potable Expansion tank

http://www.supplyhouse.com/Amtrol-141N43-THERM-X-TROL-ST-12-Expansion-Tank-3715000-p $56.75 This 4.4 gallon model is suitable for potable water systems.

You need an expansion tank to take up some of the pressure and avoid the pressure relief valve needing to operate.

It is good to have an expansion tank that is about 5% of the gallons of the water heater.

Expansion tanks should be mounted with the pipe at the top. Use a 3/4" MNPT to 3/4" PEX adapter and a 3/4" PEX Tee.

Pressure gauge

These are fairly inexpensive so it is good to sprinkle them liberally.

Use a 1/4" MNPT to 1/2" PEX adapter and a 3/4"-1/2" reducing PEX Tee.

Radiant heating zones

Radiant variable speed radiant heating pump

Variable speed

circulator pump

Variable speed

circulator pump

The pump will look at the delta temperature between the input and the return on the radiant manifold and vary its speed as needed. If the delta-T is too high then the pump will speed up.

If all zones are closed then the lack of 24V from the OR-ed 4 wire actuator micro-switches causes the radiant circulation pump to turn off. This is done by connecting the OR-ed micro-switches to the "heat demand" input on the pump.

Need to calculate the water resistance of the zone length of 1/2" radiant tubing to see if the selected pump has enough head. The calculation is given above and shows that the head required is only about 1.5 feet. The pump can do 17' head.

Note that the vertical raising of the water to the bedroom level does not count in the head calculation because it is a closed system and the water weight returns to the pump.

The pump should be orientated to pump vertically up to keep air bubbles out of it.

1/2" Oxygen Barrier PEX piping

Oxygen Barrier PEX is made from the same material, but with an oxygen barrier applied to the outside of the pipe. It is not certified for potable water because it is not cleaned the same as it is for potable water use. Also, getting NSF certification is expensive for PEX manufacturers so not having NSF certification reduces the price of Oxygen Barrier PEX pipe. Your local plumbing inspector will probably not accept having non-NSF-certified PEX used for the domestic hot water system, but it is the right choice for a closed loop radiant heating system.

For hydronic radiant heating, use oxygen barrier

1/2" pex, on 12" centers. Always use 250 - 300 ft. loops. Buy

pipe in increments of 1000 feet. OB

PEX tends to be stiffer than Non-OB so you need to check it can

handle the required bend radius.

If using a cast iron pump (which is the least expensive way to go) then you need oxygen barrier PEX. This style of tubing will save you money when buying parts and will prevent rust and corrosion.

During installation, be very careful to avoid getting kinks in the pipe.

For radiant heat applications using closed systems, barrier tubing is by far the best choice. Traditional examples of barrier tubing include Wirsbo hePEX, Thermapex Tubing, Bluefin, and HydroPEX Barrier Tubing. My choice is Bluefin as it is considerably less expensive but still perfectly ok.

Staples for half inch PEX

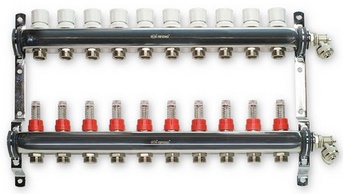

Manifold with zone valves

Supply water is connected to the bottom leg of the manifold. Balancing is done by turning the red knobs. Shutoff is done using the white knobs on the return leg.

Having the zone valves on the return manifold (rather than the supply manifold) will reduce their operating temperature and will make them last longer.

Flow meters are totally unnecessary in a residential heating system. Every system should be designed with ball valves on every loop, to make balancing simple.

There is no fundamental need to install temperature gauges on the supply and return manifolds, but analog temperature gauges come with the manifold. Alternatively you can use inexpensive ($15) digital temperature displays .

It is worth getting a manifold with enough legs to provide plenty of zones and ideally have some spare. For my house I have 9 zones and therefore need a 10 way to give me one spare leg.

The manifold comes with manual zone valves to which you need to fit 4-wire actuators.

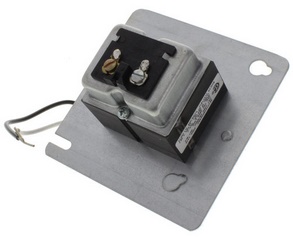

4-Wire Manifold valve actuators

Need to get the version where the micro-switch contacts are normally open, ie the switch only closes when the valve opens.

Actuators operate the valve on the return side of the manifold. They shutoff water to particular PEX loops if the zone has reached the temperature set by the thermostat. They operate from a 24V power supply (can be AC or DC). Use a 24VAC transformer.

The 4 wire version provides a micro-switch to control other equipment. One benefit of the relay is that it does not operate until the valve has opened (there is a delay from applying power to the valve actually opening because it is done by heating wax). A bigger benefit of having an isolated micro-switch is that it allows you to do a logic "OR" function to turn on the circulation pump if one or more of the zone loops is open.

The micro-switch can handle an inductive load of 1A. In practice the micro-switch is only used for low current 24V to the enable inputs on the pumps.

Auto-fill check valve

An "auto-fill check valve" connects a closed system to the potable water supply to make up for any water losses at the relief valves or small leaks.

For radiant heating systems it is more common to use 10 to 15 PSI whereas home hot water systems are more like 50 PSI.

The integrated back-flow check valve prevents water in the closed loop radiant heating loop from getting back into the potable domestic hot water.

The selected valve can be adjusted anywhere between 8 psi and 50 psi. I choose to set it to 15 psi in normal operation. Having the 50 psi capability is useful for pressure testing the system.

Air Eliminator

This is necessary on the closed loop radiant manifold loop to get air out of the system.

This model has a half inch NPT female hole on the bottom for easy attachment of an expansion tank. It is cast iron but that's ok.

Want it at the hottest point and the highest point.

Radiant expansion tank

This handles the thermal expansion of the water in the closed loop. It does not need to be rated for potable water, but I use a potable one as it's not a big extra expense.

It has a male 3/4" NPT connection on the top. It is good to connect this to the bottom port of an air eliminator, although this does need a 1/2" to 3/4" adapter.

Combination pressure temperature relief valves

Pressure Temperature Relief Valve

Pressure Temperature Relief Valve

Check Valve

Use a 3/4" check valve with adapters to 3/4" PEX.

These are used in various places to ensure the water only flows in the proper direction.

Control system

24V Relay

A free standing relay is ok if you have a box for it to go in (eg a regular wall mount electrical box)

Transformer 24V

Comes with a convenient mounting plate that can go on the top of a double electrical box. The relay can go in the same box.

Zone Thermostats

The thermostats control the 250 - 300 foot zone PEX loops. One thermostat per loop. The heating relay closes when the temperature in the zone is less than the temperature set in the unit. The relay applies 24V to the appropriate zone actuator on the radiant manifold.

Mount the thermostats on an interior wall. Mount the sensor about 5 foot off the floor in relatively still air.