Metal Roofing

My choice

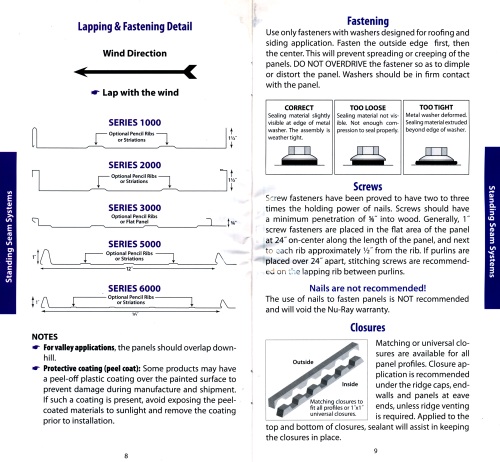

Nu-Ray Series 2000. 12" panels. 24 gauge. Pencil ribs. Copper penny color.

NU-RAY METALS

1234 37th Street, NW Auburn, WA 98001

Tel (800)

700-7228 Tel (253) 833-7228 Fax (253) 833-7268

Sales@NuRayMetals.com

Jeff is a good helpful guy at Nu-Ray.

Nu-ray makes roof panels, but they have to be purchased via distributors such as Allied. When you hire a roofing installer contractor they will buy the panels from a distributor.

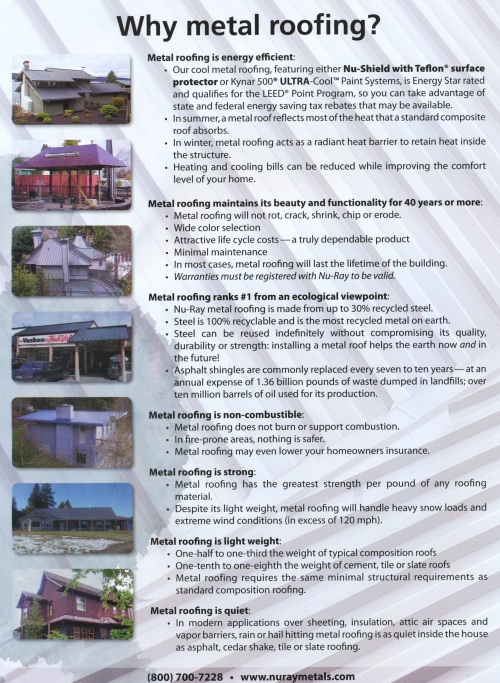

The panels are made from rolls of zinc plated steel. It is the zinc plating that provides almost all of the rust proofing. The paint is just to make the panels the desired color.

Implementation

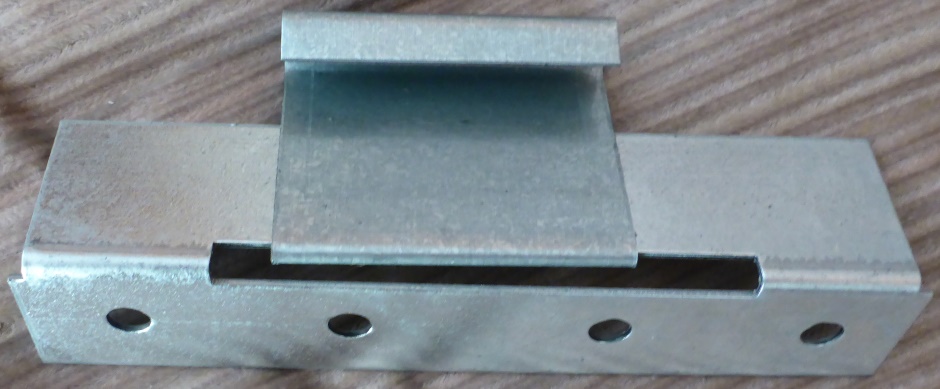

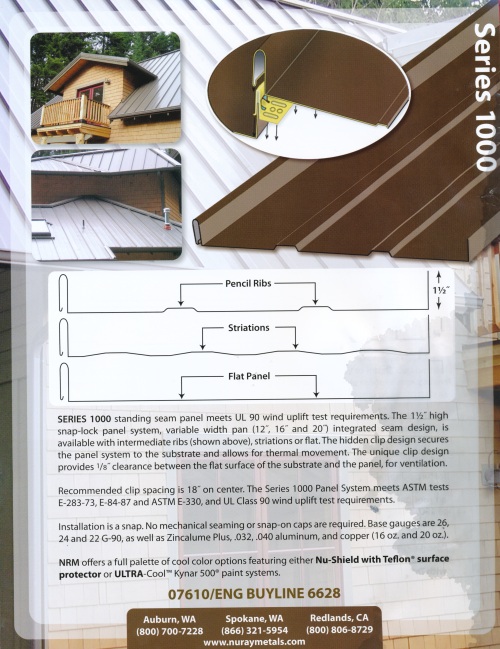

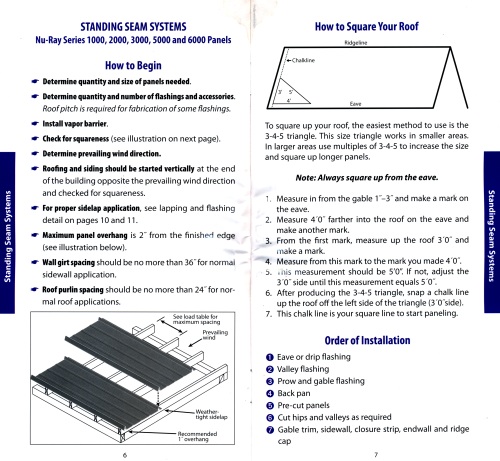

Metal roofing panels expand and contract with temperature. To allow for this a sliding clamp is used. The clamp is crimped onto the roof panel seam ahead of the panels being crimped together along the full seam. The use of clamp pieces avoids the need for any exposed screws.

The clamp fittings are designed to be screwed down onto a wooden roof deck. In my roof design there is lots of polystyrene on top of the roof decking and the roof overhang is entirely polystyrene. It is necessary to put horizontal strips of plastic 2x4 so that there is something for the clamp fittings to be screwed to. The plastic 2x4 strips are mechanically anchored to the underlying roof structure using long lengths of 3/8" threaded studding. The reason the 2x4s are made from plastic rather than wood is that they are outside the house thermal envelope and so would rot if made from wood.

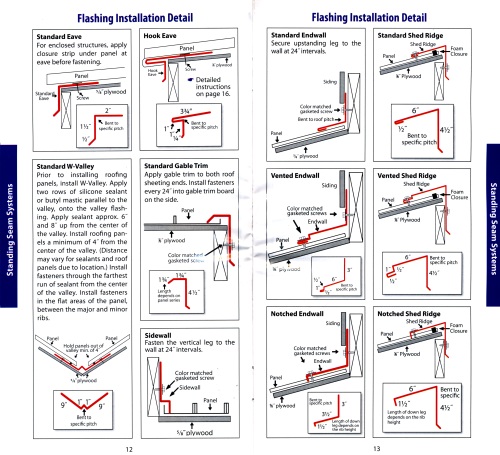

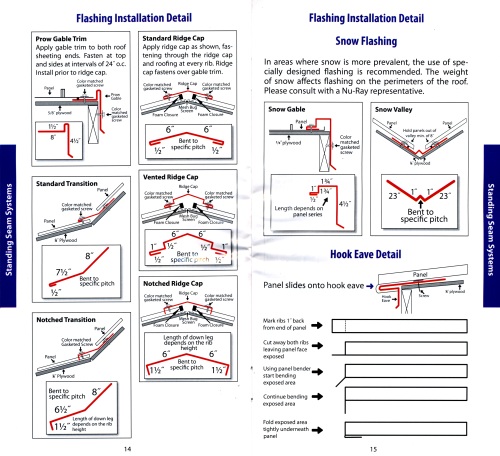

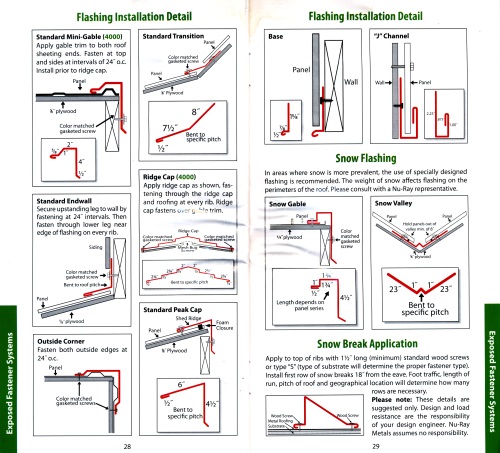

It is not possible to bend a panel and keep the seam intact so water will get in. In practice the panels will just be used for the 45 degree part of the roof. The flat part at the top will be done the same way at the flat walkway area of the roof. A 45 degree cap (adhered to the flat roofing membrane) will be used at the top to transition from the flat part. A Standard Ridge Cap piece may work.

At the bottom end it is necessary to have a plate for the end on the panel to fold over. The plate will be fixed to the bottom plastic 2x4. Parts called Hook Eves may be available.

Installers

Tecta Tom McDonald 206-522-5436

DTK Construction Paul Rose 253-691-0176

Brochure

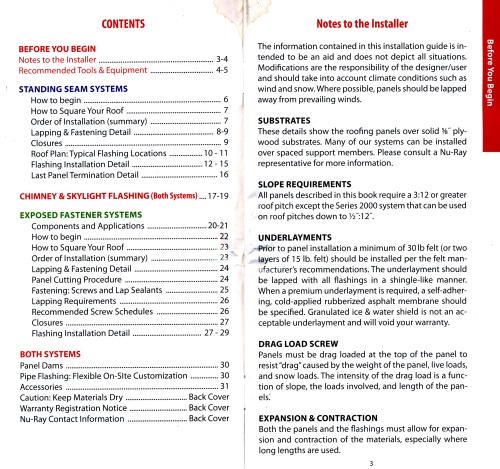

Installation Guide

Details

In my area (Seattle), the distributor is Allied Building Products (Woodinville).

Price

Roofing sheets cost about $2.40 per sqft.

Evaluation building

Each side of evaluation building is 20' wide by 8'.

For the evaluation building I need 40 panels that are 8'6" long. That's 340 sqft so price is 340 x $2.40 = $816.

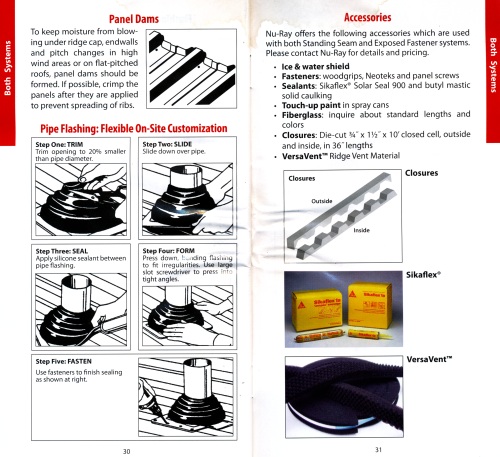

Accessories needed are...

Standard ridge $30.50

Gable (rake) $18.00

Drip edge (eve) $12.80

200 - 1" panel screws $.06/ea

250 - 1" woodgrip copper penny $.06/ea

Other considerations

Increasingly it is good to have solar panels on your roof. These will be on the south side and not on the north side. This north/south visual imbalance can look bad, in addition to the fact that solar panels are already fairly ugly. If the color of your metal roof is about the same as the color of the solar panels then the ugliness and asymmetry will be somewhat reduced. That tends to suggest picking metal roofing that is a blue grey color.