Home Site Map - Techniques - Structure -

Stucco

![]() Creating the hard shell for the building exterior.

Creating the hard shell for the building exterior.

Stuccoing

The following notes relate to straight flat stucco.

Three coats: Scratch, Brown, and Finish.

The purpose of the first

base coat, the scratch coat, is to embed the lath mesh (if mesh is used) and provide a

base for the brown coat. The scratch coat gets its name from the

fact that it is physically scratched with horizontal marks. These

scratches create a “key” for the next coat to grab onto and a shelf for

moisture to aid in curing of the brown coat. The brown coat covers

the first base coat and creates a plane surface, leading to the best

possible results for the finish coat. The finish coat is the

thinnest of the coats, and its purpose is to impart a decorative surface

to the plaster.

The final stucco finish coat will be done when all

the walls are up, ie the final coat will be for the whole house in one

go. It is worth living with the scratch coat for a while to check

it does not crack. The scratch coat will keep UV off the EPS.

If stuccoing concrete blocks or other previously set concrete then wet the surface of the blocks before stuccoing.

Products

Latex Stucco mix

To get it to stick well to the EPS and to get the layers to stick together it is best to use latex stucco. You can make latex stucco by using some Latex Concrete Additive instead of some of the water when you mix regular type-s stucco.

The Latex Concrete Additive is already about 75% water. I settled on using 3/4 water and 1/4 latex additive. This means the actual latex percentage in my stucco mix is about 5%. For an 80lb bag of type S mortar add half a gallon of latex liquid and about 1.5 gallons of water. In practice mix two bags at once (with one gallon of latex liquid). The exact amount of water should be adjusted to get the consistency (ie slump) right.

Another possibility is to buy stucco mix with the latex already added in dry form...

http://www.sakrete.com/products/detail.cfm/prod_alias/Stone-Veneer-Mortar

The stone veneer version is only a 50lb bag so the cost is twice the unmodified. Also the quality of this stucco mix is questionable and the actual latex quantity is suspiciously unknown.

Color additive

The color varies when using color additive depending on quantity. Some colors can work with a gray stucco base.

Add one bottle of Buff color liquid to two 80lb bags of gray stucco mortar.

Only the top finishing coat needs to be colored. The scratch coat and brown coat do not need coloring.

Polypropylene fibers

Using polypropylene fibers is an easier and quicker alternative to using mesh. It's not as good as using mesh, but it's ok.

BASF (2-Pack) BASF MasterFiber M70 Monofilament Micro Fiber Concrete Additive

https://www.master-builders-solutions.basf.us/en-us/products/masterfiber/1663

https://smile.amazon.com/BASF-MasterFiber-Monofilament-Concrete-Additive/dp/B01N7S6HGS/ref=pd_sbs_469_7?_encoding=UTF8&pd_rd_i=B01N7S6HGS&pd_rd_r=Z631CGC7B9XT3AW5QAV4&pd_rd_w=LReMS&pd_rd_wg=OCd3Q&psc=1&refRID=Z631CGC7B9XT3AW5QAV4

1.5 pounds $10 + $5.49 ship (shipping not bad if buying multiple packs)

Something like 40 of the 80 lbs bags of stucco mortar is 1 cubic yard

and Basf recommend 2 x 0.75 pound bags per cubic yard. For 20

bags of mortar want 1 pack for fibers. Use 2 bags of stucco mortar

per mix. I recommend using 1/8th of a bag of fibers per mixer

load.

Fiberglass mesh

If using mesh you need to apply a fiberglass mesh lath onto the first coat while it is still wet so it embeds. The second coat needs to completely hide the mesh.

It is desirable to use mesh in earthquake areas (such as my area).

Use 4oz mesh (4.5oz is fine).

The mesh is to provide reinforcement for an EPS surface so there is no need for mesh if stuccoing straight onto a concrete surface.

You may be able to avoid using mesh if you are using polypropylene fibers.

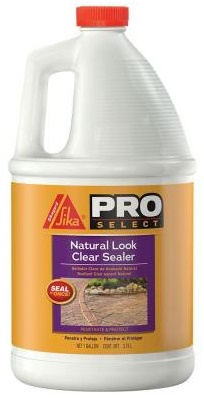

Stucco sealant

Using a sealant is optional and painting or spraying it on is extra work. It is however useful for helping shed the rain.

A better bet is to use waterproof latex paint...

BEHR PREMIUM® Basement & Masonry Waterproofer No. 875

Earthquake considerations

Need either a brick-ledge detail or balconies/decks that separate the wall. A concern in my area is seismic activity. The stucco could fall off the wall if not for intermittent bearing points.

It is important to use a mesh or polypropylene fibers so that in an earthquake the stucco holds together. Ideally the mesh would be mechanically attached to the wall, but in my case this is hard to do because there is 8" of EPS on the wall. Wrapping the continuous mesh into window openings will help. Ideally this would wrap under the window nailing edge and thus be secured by the window screws.

Can potentially also make use of the tie rod bolt holes to hold on the mesh. Don't use galvanized wire as it will rust away. Could perhaps use say 3" nylon bolts that are held into the conduit holes using foam gap filler.

Traditional stucco is about 10 pounds / square foot.

Tools

Concrete Mixer

When mixing the stucco it is best to use a concrete mixer as it is less work and achieves a better mix consistency.

Spray guns

Spraying is necessary for architectural details such as EPS cornices and EPS drip edges.

If it has more jets then it needs a bigger compressor. Ideally I just want 1 jet, but can use stoppers with the other jets to make a 3 jet into a 1 jet.

http://www.amazon.com/Plaster-Sprayer-Stucco-jets/dp/B004HE58JI

http://www.amazon.com/MARSHALLTOWN-Premier-693-SharpShooter-Adapter/dp/B00023S15G/ref=pd_cp_hi_3 $83

My existing sprayer is probably still the best bet.

Implementation

Mask window frames

Use some blue painter's masking tape to avoid getting stucco or filler foam on the face of the window frame.

Form EPS details

Things such as window sills, drip edges, and the divider between backfill coated wall and above ground wall. Because in my case the windows are recessed into the wall I can use EPS to form a drip edge above the window rather than needing metal flashing.

There should be a 1/4" gap around the windows. This will get filled with foam gap filler.

You can avoid expansion joints if the stucco length is less than 100 feet and the substrate is totally rigid, eg a concrete wall.

Prepare EPS surface

The wall has two layers of EPS sheeting. One of the things this means is that there will be no visible screws or washers as the top sheet is glued to the inner sheet (that is held into the wall concrete using cable tie tails).

After the EPS sheeting is all in place, the first job is to rasp off any high spots and any excess foam. You also want to take off any surface dust that has happened due to UV exposure.

Cut fiberglass mesh

This is only if you decide to actually use mesh. Because of the quick drying time you need to have the mesh cut to all the right sizes ahead of time.

Thickness and drying

The scratch coat should measure 3/8" thick. It should moisture-cure for 48 hours before the brown coat is applied. In dry climates or windy weather, keeping the stucco moist during the curing period may require more frequent wetting.

Allow another 48 hours to moisture-cure the brown coat, which should also be 3/8". Then let it dry-cure for 10 days. Extra curing time minimizes cracking.

The colored finish coat should measure at least 1/8" thick.

The final assembly should measure no less than 7/8 inch thick. Some codes may only require a total 3/4-inch thickness, but that’s too thin and will lead to cracking.

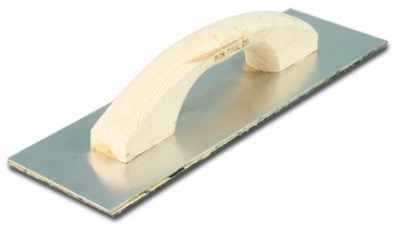

Apply base coat and optional fiberglass mesh

Use a flat mason's trowel to apply the base coat stucco. While the stucco is still wet for a particular wall section, apply the fiberglass mesh (optional). Use the large flat trowel to push the mesh into the surface of the stucco. If you need to add some additional stucco base over the mesh then do so to cover the dry spots. No dry bits of mesh should be visible.

The thickness of the scratch coat should be 3/8" - 1/2".

Over the surface use a rake trowel to scratch the surface.

Add brown coat

This layer thickness should be 1/4" - 3/8".

Make good the base coat surface

Using a large flat sanding rasp or block, make sure the stucco cement surface is free from any high spots or burrs.

Apply primer (Optional)

This is optional. It helps seal the wall and helps the finish layer to stick. It is only really needed for a very flat brown coat.

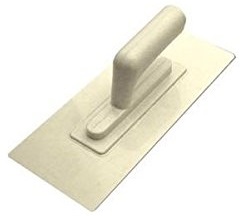

Apply finish stucco coat

The largest aggregate is the thing that sets the thickness of the coat. Typically the finish coat thickness you want is 1/8".

Stucco color is typically added to the stucco used for the final finish coat.

Avoid doing it in direct hot sun or it will dry too quickly.

Before the finish coat has dried, use a plastic faced large float to smooth and polish the surface and remove any high spots and trowel marks. Keep the float slightly wet.

Permeance

Latex modified Portland stucco has a low permeability - as low as 1 perm. That is a problem if you put it over wood sheeting as it does not allow moisture to escape, but for me the low permeance is exactly what is required as it keeps rain out of the wall EPS.

Expensive proprietary stucco brands

The 3 main players in lightweight vertical wall application are Flex, Concote and Surespray.

Dryvit

Dryvit will stick to nearly anything and is a forgiving coating. It is "elastomeric" which means it is not brittle and will withstand major temperature fluctuations. It can be sprayed with a hopper gun or brushed on. Dryvit is a brand name and there are many other similar products used by the stucco industry. The undercoating product known as "browncoat" is actually an excellent foam coating and can be sanded. It gives the foam the hardness that is needed before the Dryvit type products (latex stucco) are applied. Find your local stucco supplier...... Bonsal and Parex are common product names. Your local supplier will carry a complete brand "system" that includes the browncoat and stucco. Google "Elastomeric Coatings" and you should find a wealth of info. Dryvit is just one of several brands. Browncoat.... which is also known as flex-base. Other national brands that compete with Dryvit and may have local distributor willing to sell to you. You can search their websites for closest distributor. www.parex.com and www.stocorp.com . This site looks good http://www.stocorp.com/index.php/en/200907083/Contractor/contractor/menu-id-3.html Distributors of StoCorp...

Miller Paint Company 13800 Bel-Red Road, Bellevue (425) 289-0096

Evergreen Building Products 11025 117th PL, NE, Kirkland (425) 828-6121 http://www.evergreenbp.com/

http://www.evergreenbp.com/sto?cdtScript=1&cdtWidth=1373&cdtHeight=880

Acrylall

Acrylall BASTION Exterior Texture Coating (Stucco alternative) http://acrylall.com/environmental-edge/

The Garrison covers an average of 135sf per 5gal pail. This is for the 1st coat to lay on the mesh and the 2nd coat to cover the mesh together. The Bastion covers an average of 135sf per 5 gal pail. This is for 2 coats finish.

How to videos

There are a series of training videos (done by TotalWall) starting at https://www.youtube.com/watch?v=IfVKNK3IO1w

http://www.totalwall.com/index.php?option=com_content&view=article&id=4&Itemid=105

http://www.ehow.com/how_6317879_apply-acrylic-stucco.html

http://thestuccoguy.com/what-is-stucco-exactly/

https://www.youtube.com/watch?v=XnuznRkJtow

Probably only the finish coat stucco is white.

https://www.youtube.com/watch?v=gcHc-o1O4eQ

https://www.youtube.com/watch?v=_OloldpTF-g

Look at EIFS videos

https://www.youtube.com/watch?v=_GDEBxsooZ8

https://www.youtube.com/watch?v=t5GzlKrIHv8

https://www.youtube.com/watch?v=CgftrPVPzCs

https://www.youtube.com/watch?v=W_BU_be3Y5U

http://www.mortarsprayer.com/video-gallery/

Contractors

PJ Super Construction

Dryvit said: "PJ Super Construction is an

installer of Dryvit Systems".

Jerry Yaroslav Petrechko (Owner)

206 227 1966

PO Box 68127, Seattle, WA 98168

1819 Central Avenue S # 59

Kent,

WA 98032-7505

http://www.manta.com/cmap/mm72klq/p-j-super-construction-inc

(253) 639-4758

Jerry can if required do a "fake brick" look.

Fake brick

This is not what I do.

https://www.youtube.com/watch?v=phInQASolq4

https://www.youtube.com/watch?v=zllHde3z5u0