Home Site Map - Steps - Foundations -

Foundation Lining - Final Tough-Liner

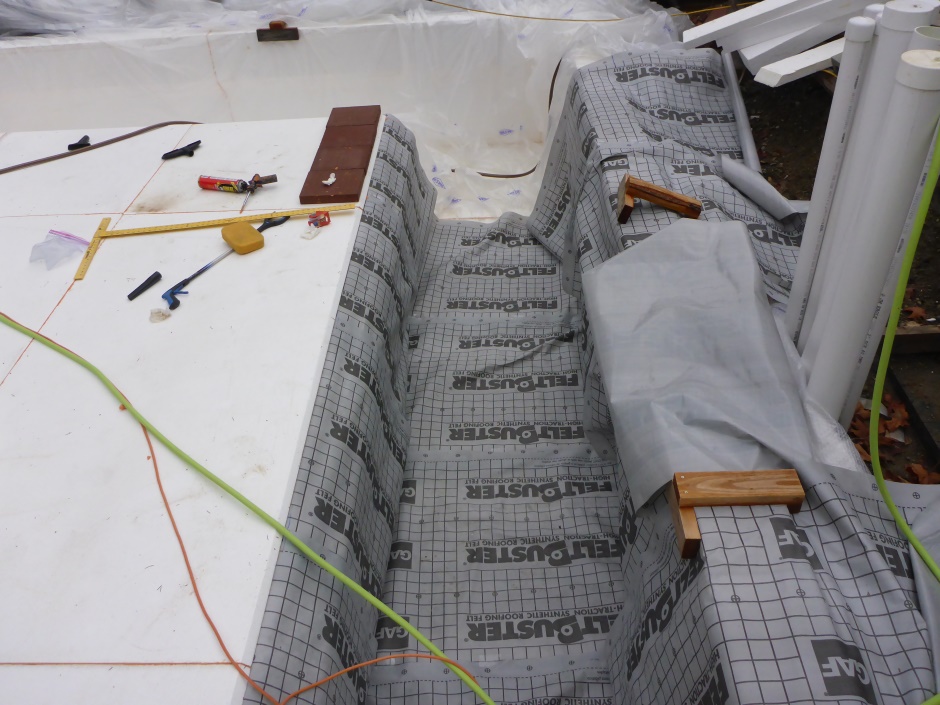

![]() In the trenches Tough-Liner is used to protect the waterproof

membrane from the rough concrete.

In the trenches Tough-Liner is used to protect the waterproof

membrane from the rough concrete.

Line footing trench with Tough-Liner

Function

The aim of using this layer of Tough-Liner in the footing trench is to protect the polyethylene official waterproof membrane from being damaged by the concrete or the concrete vibrator during the pour process. It is not practical to use 1" EPS in the footing for this protection as it's too hard to keep in place.

Implementation

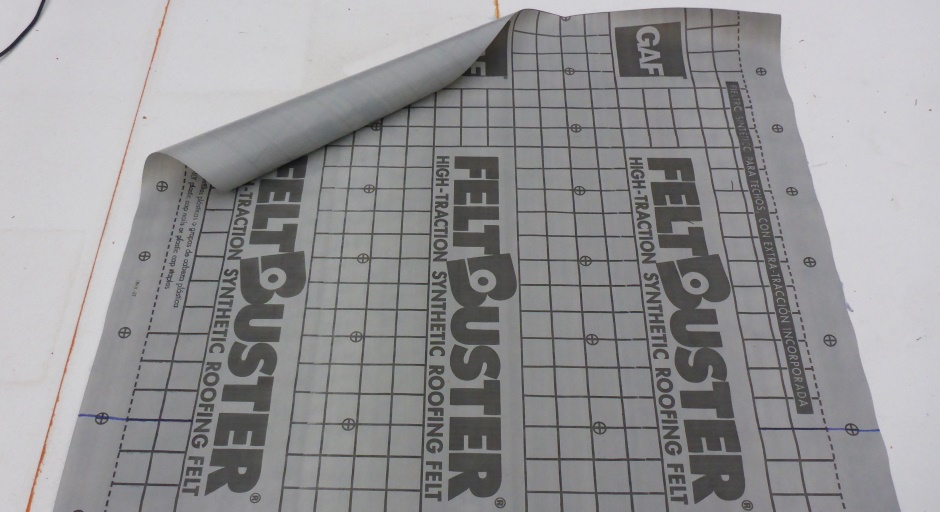

Use strips of Tough-Liner that U into the trench. The strips have enough length to provide good protection on both the outside and the inside. You want 1' overlap onto the slab area and 3' beyond the outer edge of the outer upper form-a-drain. The extra beyond the form-a-drain is used to keep sunlight UV off the rolled up polyethylene membrane.

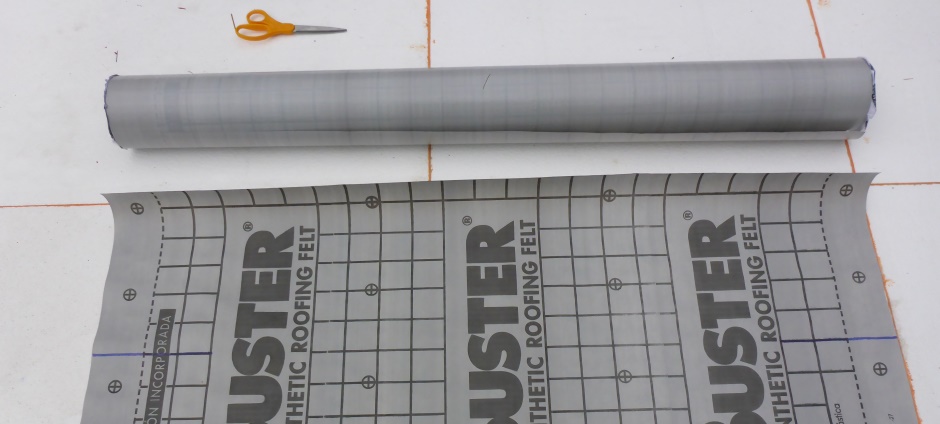

For the perimeter footings I cut the Tough-Liner to a length of 15'6". Put marker pen marks at one end 1 foot from the end.

Mark the other end at 3 foot.

Provide about 4.5" of overlap between the strips. Use a marker pen to indicate the line corresponding to the overlap.

For internal footings the length is 12 feet with markings 1 foot from each end.

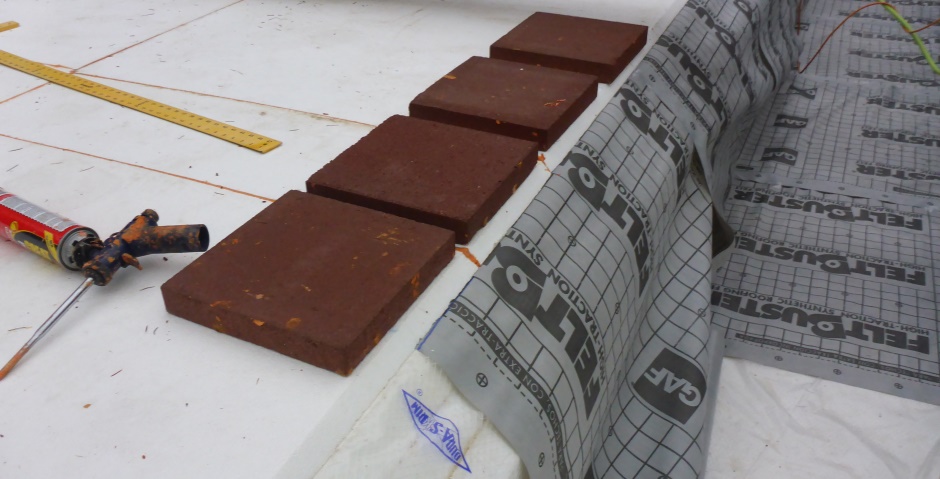

It goes under the 1" EPS that is over the slab area so you need to lift up the EPS to fit the Tough-Liner. Put a couple of line beads of foam gap filler on the Tough-Liner under the EPS and then weigh it down with paving slabs for the 15 minutes it takes to dry. The foam holding the Tough-Liner is a little dependent on what you use as the Tough-Liner but typically synthetic roofing felt has a slip free surface which also makes it glue well on that side.

Use a T square to get the strips properly square across the trench.

Use the wood clamps to hold the form-a-drain end. The 3 foot marks should be positioned to correspond with the outer edge of the Form-a-drain. The wood clamps will stay in place until the concrete pour has reached up to about 6" from the top of the Form-a-drain.

Use a wet/dry vacuum cleaner to get dirt and the bulk of the water off the polyethylene sheet before putting the Tough-Liner over it.

Use lengths of duct tape to form a continuous seam between the sheets. It will not be a fully waterproof seam but it will be good enough to stop dirt getting under the Tough-Liner .

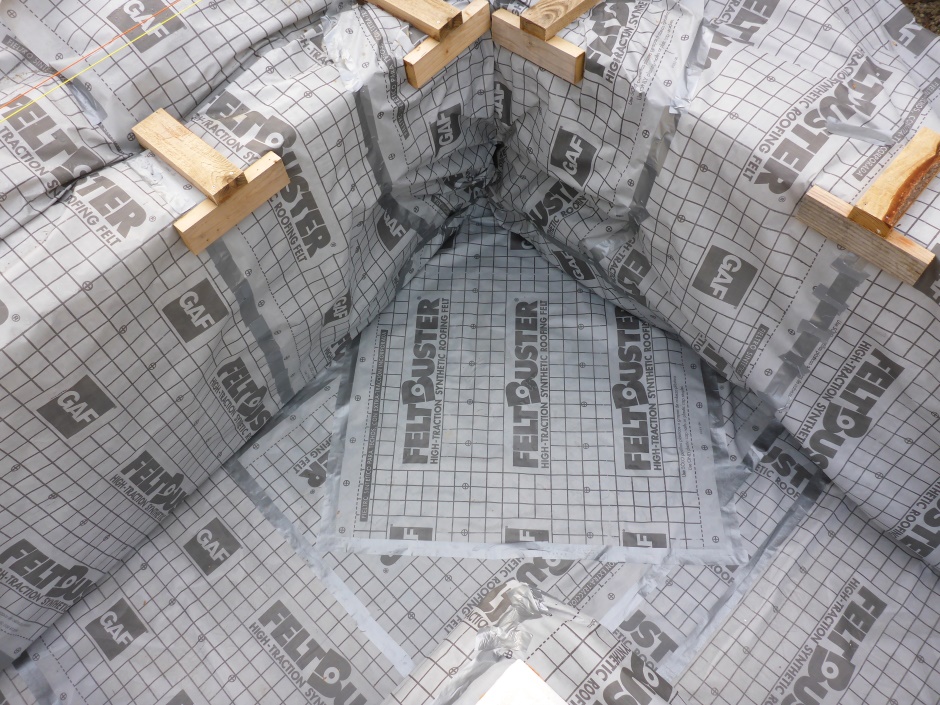

At corners it is more complicated. On a convex corner you will need a north-south piece and an east-west piece, then a diagonal piece in from the corner...

On the internal wall cross areas it takes even more creativity to patch together pieces of Tough-Liner ...

Put back lumber bracing (if required)

Depending on how much earth backfilling has previously been done and the characteristics of your soil and how much rain is expected, you may feel that putting back the lumber bracing is a good safety feature. These are the 3'3" lengths of scrap lumber that use pads at each end.