Home Site Map - Techniques - Electrical -

Solar Power

![]() Generating electricity from the sun.

Generating electricity from the sun.

My Solar System

My priorities

I do not trust the power utility company to give a good electricity buy price or even to deliver power as and when they have a crisis. As such, a grid-tied solution is not what I want. Most important to me is an off-grid solution, although I would ideally like to add a mechanism to feed electricity into the grid (to reduce my electric bill) for the summer months when I generate more electricity than my batteries can store.

I want to do things incrementally. I want to buy additional panels and batteries over time. I want to start with an off-grid system and then possibly look to add a grid feed-in mechanism later.

System design

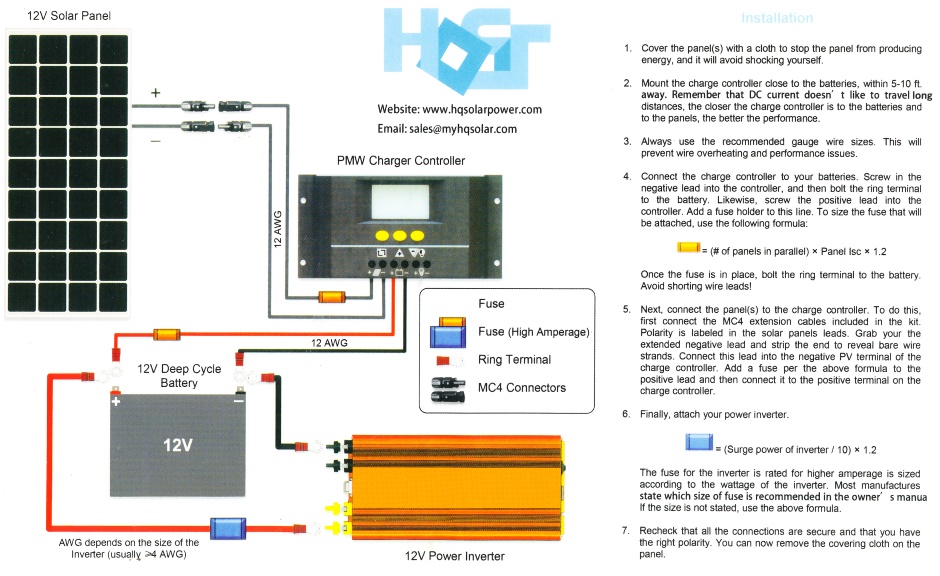

There are two basic sizes of panels - 36 cell or 60/72 cell. The 36 cell type produce about 18V for charging 12V batteries via an MPPT or simple low cost PWM charge controller and produce about 100W. The 60/72 cell type have an output voltage of about 36V and produce about 200W and need a more expensive MPPT (Maximum Power Point Tracking) charge controller to charge 12V batteries. My choice is 36 cell with a MPPT controller.

Some PV cells are monocrystaline and some are polycrystaline. Mono is slightly more efficient and slightly more expensive, but the difference is fairly small these days. The choice between mono and poly does marginally affect the dimensions and aspect ratio of the panel. Mono panels are taller and less wide. My choice is mono.

There are various low cost 100W panels available for a bit over $100 each. If using mono panels then each is a bit less than 4' tall and 2' wide. 12 or 13 foot is a sensible width for a row of panels so that means 7 panels per row. Each panel gives about 5.8A so 7 panels is also the right number for feeding into a 40A controller.

It is expensive to route low voltage DC over distance so it is best if the Controller, Batteries, and Inverter are all housed directly under the solar panels.

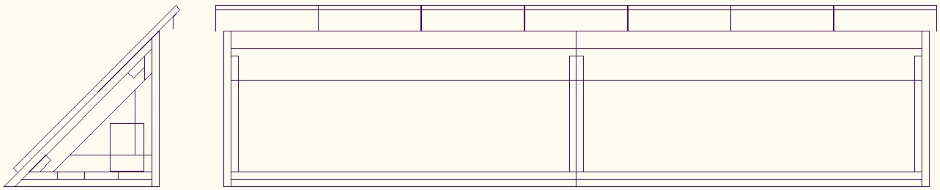

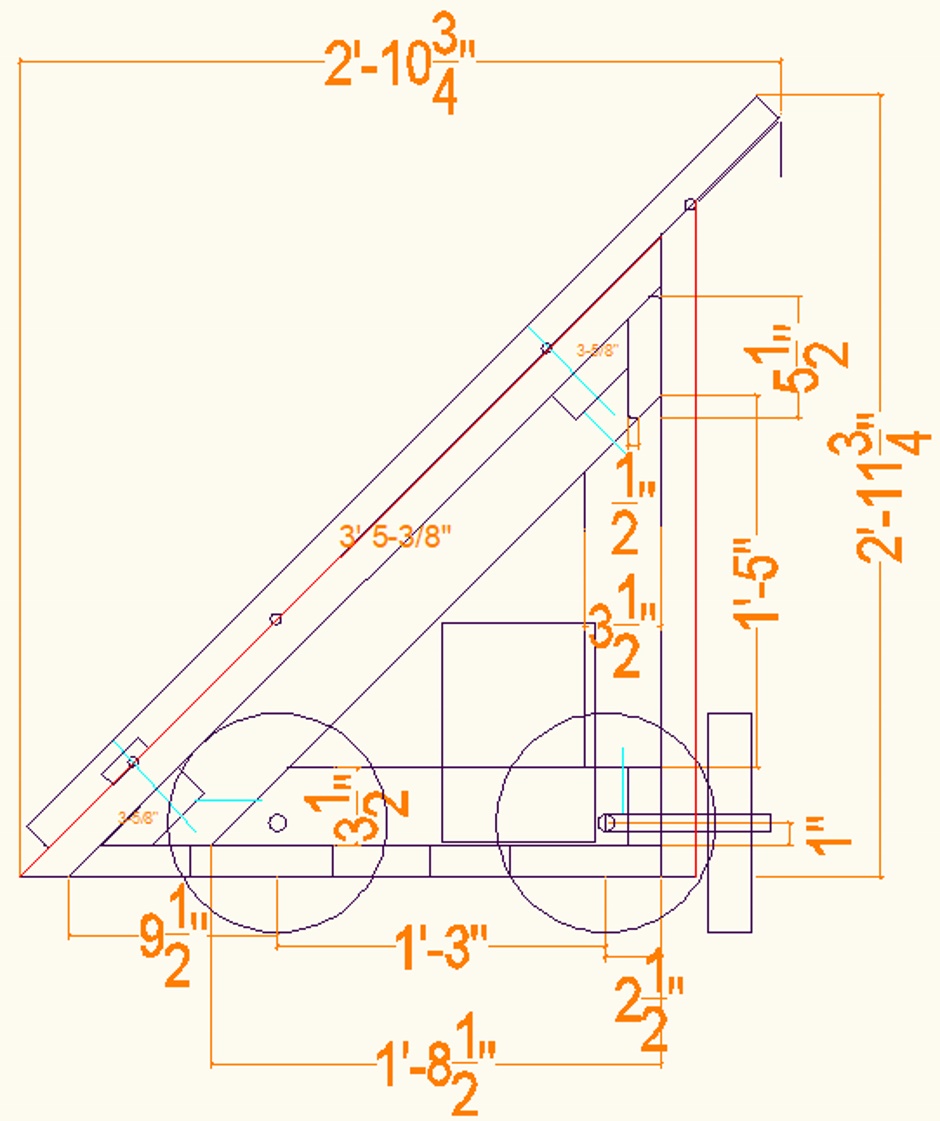

To position the panels at 45 degrees, make a triangular wooden framework out of 2x4 lumber that is rain-proof. It is good to avoid sub-zero temperatures for the batteries, so the box should be insulated with 1.5" thick EPS polystyrene on the outside of the 2x4 wood frame. It is also best to avoid the battery temperature being too high, so some thermal mass done with concrete blocks within the insulated enclosure is also good. Concrete blocks also stop the enclosure being blown over by high winds. Over the EPS use self adhesive roofing felt to keep water out and keep UV off the EPS.

Inside the enclosure you need some number of deep-cycle batteries connected in parallel and fed from the charge controller. Having batteries in parallel will spread the draw out over multiple batteries and your batteries will last longer. Deep cycle RV batteries with something like an 90AH capacity are a good choice. The number of batteries depends on your storage needs. You want the battery cluster to be fully charged by your panel cluster in a typical day. Each 100W panel can give about 25AH so 7 panels can give about 175AH per day. That would suggest 2 batteries are about right for a 7 panel rig. My recommendation is to start with 2 batteries and then add more as and when you decide you want more storage.

It is good to have a DC power meter to monitor the voltage and current coming from the paralleled panels going into the charge controller . Given that you want to be able to easily see the LCD screen on the meter it is best to mount this remotely inside your house. Three thin wires are needed to connect to the remote meter.

At the house end of the 115V wire from a solar rig it is good to provide a 115V AC power meter so you can see how much power you are taking from the battery bank inside the solar rig.

Some people like to use 12V house lights that can be fed without incurring the power loss associated with the 115V Inverter. This however ignores the losses and expense associated with feeding 12V DC from a remote solar setup. When 12V lights are used in the house, I recommend going via the 115V feed and using a switching power brick to make it back into 12V.

The amount of power you get from a sensibly affordable solar system is not going to be anything like enough to run all the appliances in a large house. I recommend providing separate dedicated 115V power sockets (next to the regular power sockets) that are clearly labeled as "Solar". You can then choose to plug particular appliances into solar. The same applies to light strings that can be plugged into one of two places. As well as avoiding the transfer switch function, choosing solar for some appliances will reduce your electricity bill without the complication of feeding power back into the grid. It also allows multiple 7 panel rigs to be used without having to provide an imperfect mechanism for ganging together multiple rigs.

Power to your appliances mainly comes from your battery cluster rather than from the panels. You can take way more power from your solar rig than the 7 x 100W panels implies, but obviously the discharge time will get shorter. It is good to have an inverter capable of a bit more than twice that of the wattage of the panels. An important feature of the selected inverter (and/or charge controller) is that it shuts off before the batteries become overly discharged because overly discharging reduces battery life. My choice is a 2000W inverter so the maximum 115V current is about 17A (call it 15A so you can use 14/2 wire).

100W panels

Renogy seems to be the highest volume 12V panel manufacturer. This means it's the most common dimensions (47 x 21.3 x 1.5 inches for mono). It is best to stick with Renogy dimensions so that future panel purchases are more likely to be compatible.

NewPowa

Newpowa Monocrystalline 100W 100 Watt 12V Solar Panel High Efficiency Mono Module RV Marine Boat Off Grid

https://smile.amazon.com/gp/product/B01LY02BOA/ref=ox_sc_act_title_1?smid=AV16HZDTPF1LD&psc=1 $107.90

http://www.newpowa.com/product-p/npa100s-12.htm

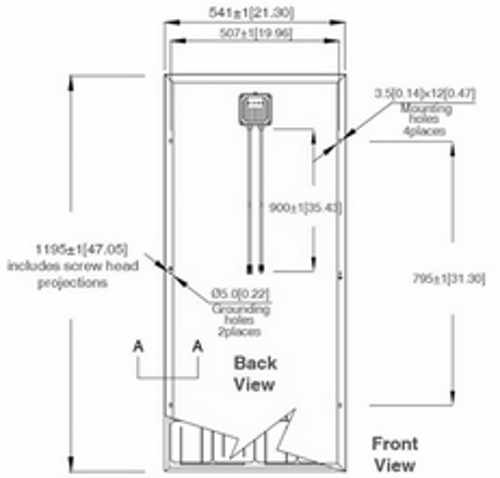

47.05in. x 21.3in. x 1.18in

Made in Mexico with non-Chinese cells.

Renogy

https://www.amazon.com/dp/B009Z6CW7O $139.08

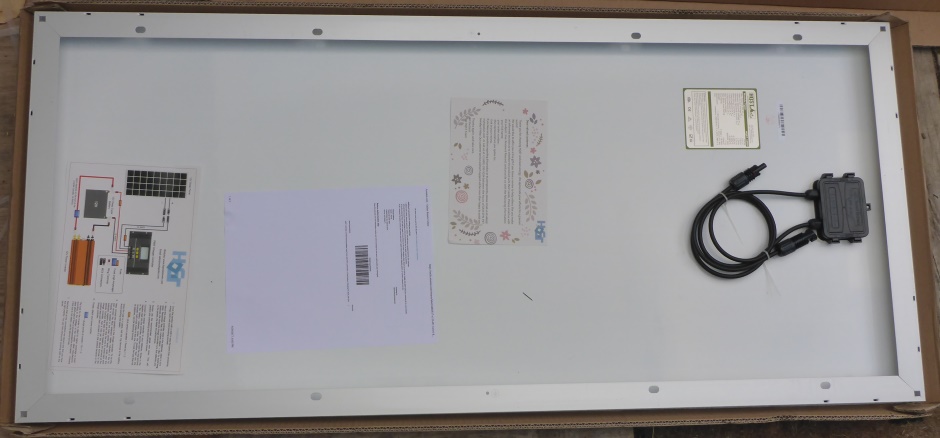

HQST Mono

They no longer seem to do this particular panel variant.

Monocrystalline

3'11" x 1' 9-3/8" x 1-1/2" (47" x 21.3" x 1.4")

HQST 100 Watt 12 Volt Monocrystalline Solar Panel with MC4 Connectors 12 Volt Battery Charging RV, Boat, Off Grid

https://www.amazon.com/gp/product/B018BMGTTO/ref=ox_sc_act_title_1?smid=A2D22KZJD14Y8Y&psc=1 $108.99 - $124.99 (No tax, free shipping)

Renogy is manufacturer and HQST is a distributor.

Similar to Renogy 100 Watts 12 Volts Monocrystalline Solar Panel

Eco-Worthy

100 Watts 12 Volts Monocrystalline Solar Panel

https://www.amazon.com/ECO-WORTHY-Watts-Volts-Monocrystalline-Solar/dp/B00V4844F4/ref=cm_cr_arp_d_product_sims?ie=UTF8 $104.99 (No tax, free shipping)

Reviews not as good. Half an inch longer than Renogy.

Battery Cluster

Need a deep cycle batteries rather than regular car batteries.

An RV

battery is a deep cycle battery and a good choice.

CCA or cold cranking amps is how they measure the number of amps that a battery should be able to deliver at zero degrees for thirty seconds and not dropping lower than 7.2 volts. The amp hour figure or AH is the rating that is found with the deep cycle batteries.

Length: 12-3/4", Width: 6-3/4", Height: 9-1/2"

Length: 12-3/4", Width: 6-3/4", Height: 9-1/2"

Costco deep cycle grp 27 12v battery Interstate 27DC Interstate model

SRM-27 Costco Item# 850982.

95 amp-hours.

http://www.interstatebatteries.com/m/category/rv/rv-deep-cycle $80 + tax

Charge controllers

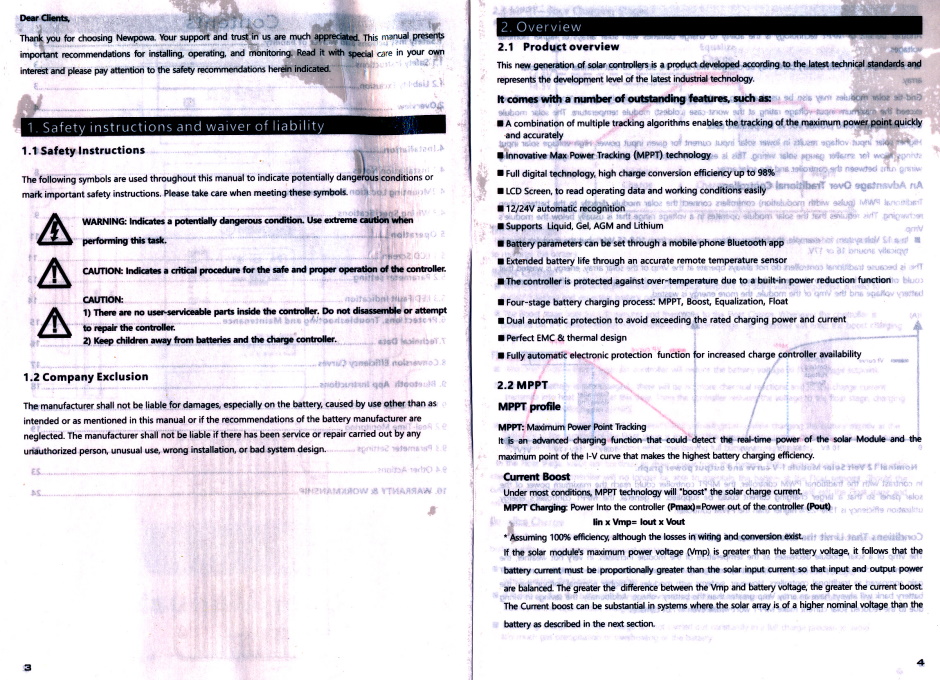

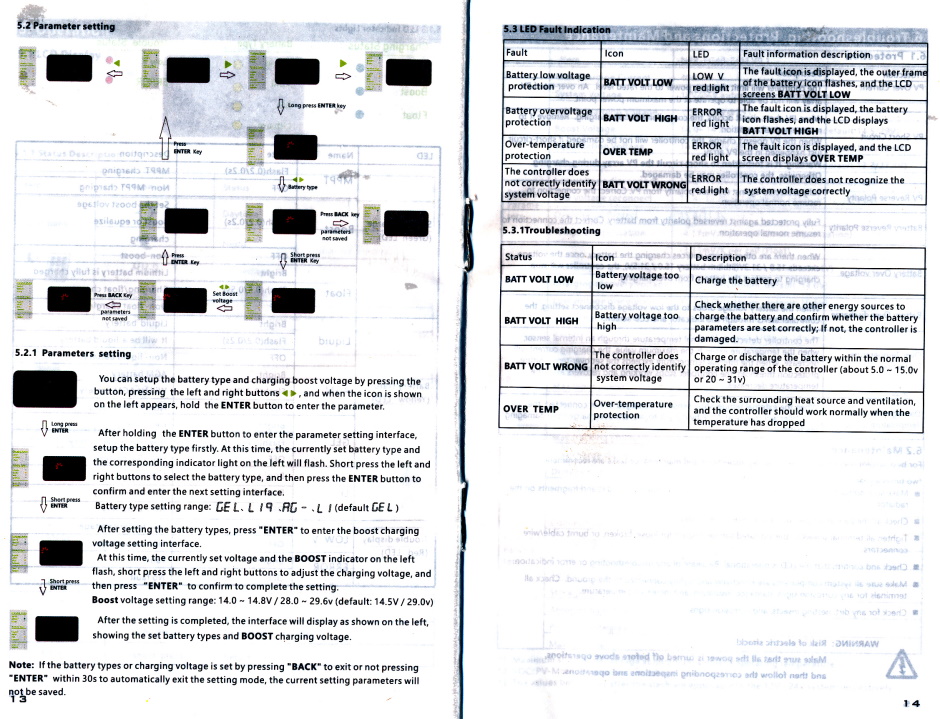

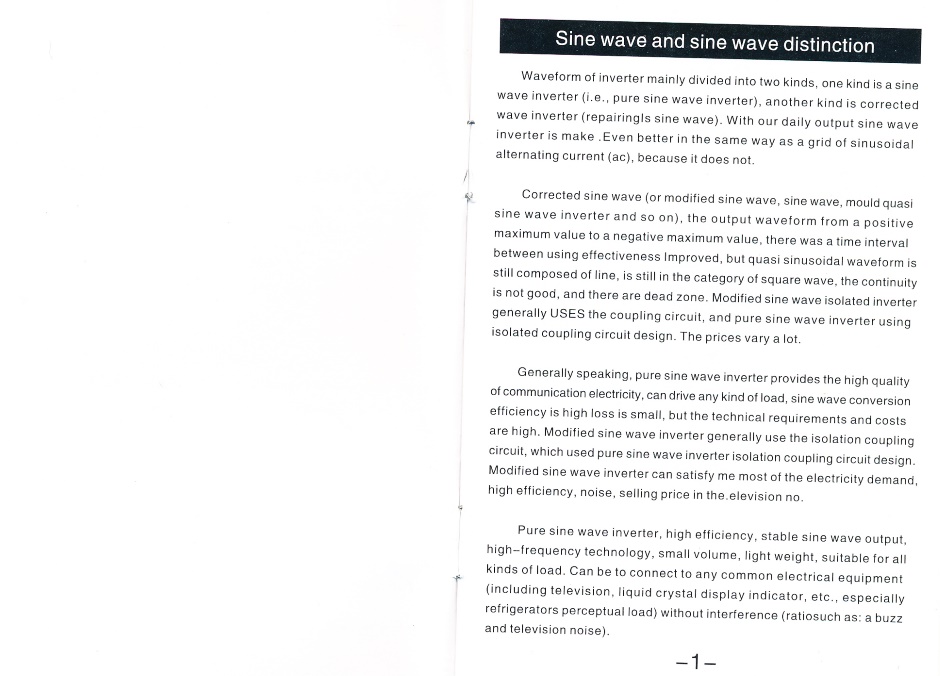

There are two types of charge controllers - PWM (Pulse Width Modulation) and MPPT (Maximum Power Point Tracking). A PWM controller does not alter the voltage to the batteries but does vary the connection time for a variable period of time to ensure the batteries are not damaged by being over charged. It also clamps the voltage to that required for battery charging, throwing away any excess voltage. An MPPT charge controller contains a DC to DC converter to vary the voltage to produce the optimum charging voltage to the batteries. It converts excess voltage into additional charge current. It can increase overall system efficiency by up to 20% and is essential when using higher voltage (60/72 cell) panels, but MPPT controllers cost more than PWM controller.s

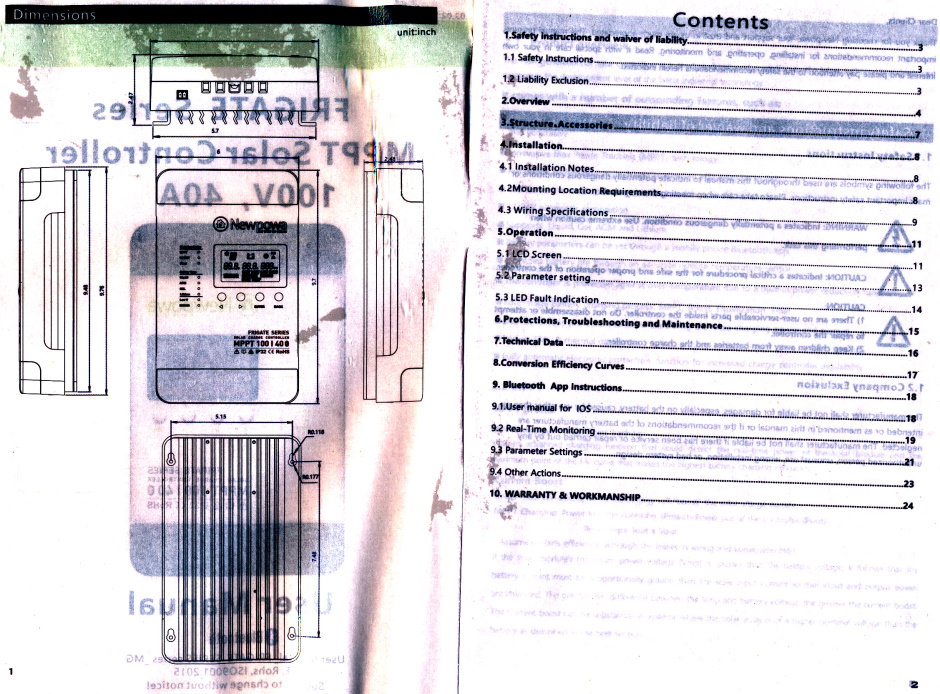

For my system design I want a charge controller with as high a current rating as possible, consistent with the price not being more than $100. The higher the current rating, the more panels can be connected in parallel as part of a "Panel Cluster". A 40A controller is about $100 and can handle 7 panels.

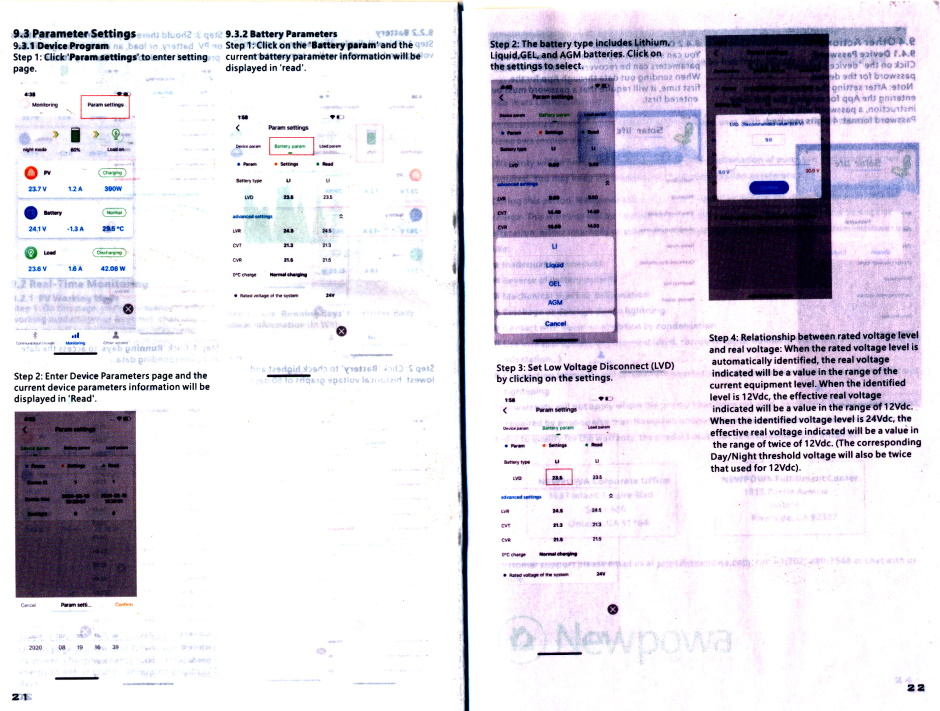

https://www.newpowa.com/new-40a-mppt-charge-controller $99 when on sale.

Inverter

2000W.

2000W Car Power Inverter DC 12V to AC 110V Modified Sine Wave Converter USB Ports Adapters

https://smile.amazon.com/gp/product/B07458K4Y1/ref=ox_sc_act_title_2?smid=A1LCONRNAYWNI1&psc=1 $109.99

GFCI

OAONAN GFCI Adapter Portable Receptacle 15Amp with One Outlet and Male Plug in Circuit Breaker to Protect Electric Safety (Black)

https://smile.amazon.com/gp/product/B06XTQF6G6/ref=oh_aui_detailpage_o07_s00?ie=UTF8&psc=1 $13.98

Socket plug 5 pin

The socket is a useful thing to have fitted to the enclosure. The plug is only used in the case of an optional DC power meter or external charging of the batteries.

5 pin Plug & Socket - TOOGOO(R) 16 Amp 5 pin Plug & Socket Weatherproof IP44 3 Phase 380-415v 3P + N + Earth 16A

https://smile.amazon.com/gp/product/B01DXF8WEE/ref=oh_aui_detailpage_o03_s00?ie=UTF8&psc=1 $9.34

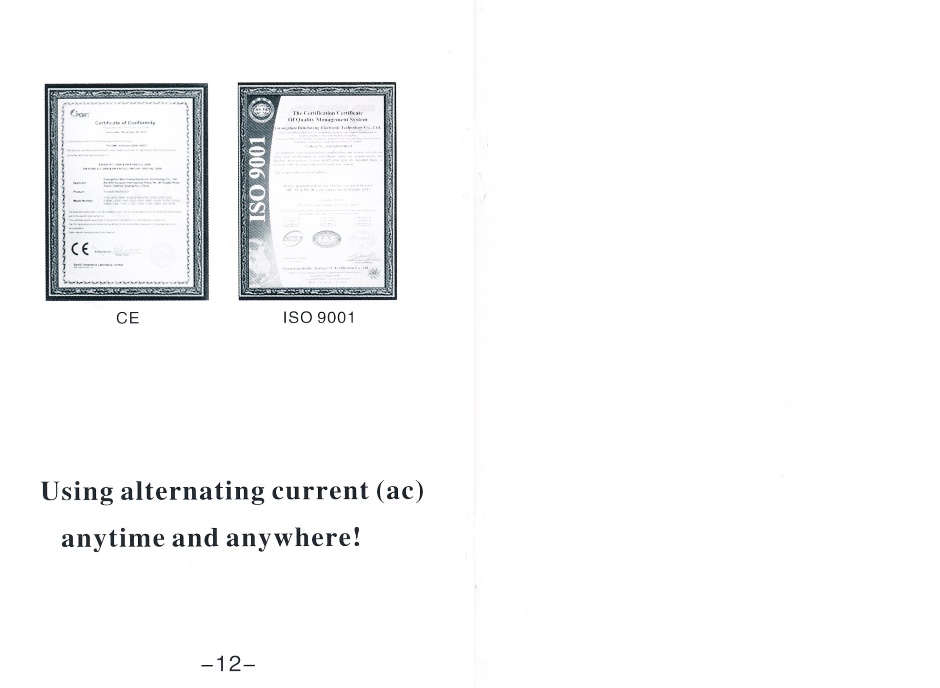

Wires

Short wires connect the panels together in parallel at the panels. In practice it is best to put 4 panels in parallel and connect back to the charge controller, and then another 3 panels in parallel that also connect to the charge controller. The wire from each of the 4 (or 3) panels needs to be able to handle 4 x 5.8 = 23.4 amps. That equates to 10 AWG wire.

The wire from the controller to the batteries needs to be able to handle 40 amps, so 8 AWG.

The link between the batteries needs to handle about 70% of the 1,725 / 12 = 144 amps that the inverter can draw. That's about 100 amps. That equates to 2 AWG wire.

Wires to the remote meter socket are 8 AWG for the battery wires and 12 AWG for the sensor wires.

Paralleling panels

Need two pairs.

Sumnacon® MC4 Solar Style Branch Panel Cable Connector (Y Type(1 to 4))

https://smile.amazon.com/gp/product/B010PBPR1K/ref=oh_aui_detailpage_o06_s01?ie=UTF8&psc=1 $17.99

Connection to charge controller

Need MC4 to bare ends for screw terminals on charge controller.

Connection from charge controller to battery

Need to remove the MC4 connectors. Need two pairs.

10AWG 1 Pair Black + Red Solar Panel Extension Cable Wire MC4 Connector with 5/16 Tin Plated Terminals,MC4 Solar Adaptor Cable (5 FT)

https://smile.amazon.com/gp/product/B076GY3W3R/ref=ox_sc_act_title_1?smid=A1XFKG8BY6TBEM&psc=1 $13.69

10AWG 1 Pair Black + Red Solar Panel Extension Cable Wire MC4 Connector with 5/16 Tin Plated Terminals,MC4 Solar Adaptor Cable (3 FT)

https://smile.amazon.com/gp/product/B076GYKPRT/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1 $11.69

Battery linking

Need one set to connect the two batteries.

2 AWG Gauge Red + Black Pure Copper Battery Inverter Cables Solar, RV, Car, Boat 12 in 5/16 in Lugs

Fixings

Panel fixing threaded rod

Each panel needs 4 lengths of 5-1/2". For 7 panels a total of 28 lengths are needed, that's about one and a half of the 10' lengths at a total cost of about $6.

STEEL CITY 0.25-in x 120-in Standard (SAE) Threaded Rod

https://www.lowesforpros.com/pd/STEEL-CITY-0-25-in-x-120-in-Standard-SAE-Threaded-Rod/1087267 $4.47 for 10 feet

Spiked 1/4" nuts

Need 8 per panel so a total of 56. Total cost $5.60.

The Hillman Group 180297 Pronged Tee Nut, 1/4 20, 100-Pack

https://smile.amazon.com/gp/product/B000H61YF2/ref=oh_aui_search_detailpage?ie=UTF8&psc=1 $9.95 for 100

3/4" long 1/4" bolts

Need 4 per panel, so 28 total.

Hard-to-Find Fastener 014973100032 1/4-20-Inch x 3/4-Inch Course Hex Bolts, 100-Piece

https://smile.amazon.com/gp/product/B004S6RZPK/ref=oh_aui_detailpage_o08_s00?ie=UTF8&psc=1 $9.84

1/4" washers

Need 56. About $2 total.

Steel Flat Washer, Plain Finish, ASME B18.22.1, 1/4" Screw Size, 9/32" ID, 5/8" OD, 0.065" Thick (Pack of 100)

https://smile.amazon.com/gp/product/B009OJIH7G/ref=oh_aui_detailpage_o09_s00?ie=UTF8&psc=1 $3.45 for 100

1/4" nuts

Need 28 for going on the enclosure end of the threaded rod. Total cost about $2.80.

1/4"-20 Stainless Hex Nut (100 Pack), By Bolt Dropper, 304 18-8 Stainless Steel Nuts

https://smile.amazon.com/gp/product/B06X1FNS96/ref=oh_aui_detailpage_o08_s01?ie=UTF8&psc=1 $9.25 for 100

Power distribution

In-house sockets

Surge Protector TechSimple 4-Outlet Power Strip 4-Port Smart USB Charger Socket Power Strip Smart USB Charger Socket with 1500 Joules Surge Protection (USB Charger Socket Power Strip)

https://smile.amazon.com/gp/product/B074KR1HBL/ref=oh_aui_detailpage_o07_s00?ie=UTF8&psc=1 $16.99

AC power meter

P3 P4400 Kill A Watt Electricity Usage Monitor

https://smile.amazon.com/gp/product/B00009MDBU/ref=ox_sc_act_title_1?smid=ATVPDKIKX0DER&psc=1 $16.67

Extension cord

Utilitech 100-ft 10-Amp 125-Volt 1-Outlet 16-Gauge Lime Green Outdoor Extension Cord

Build instructions

Fixing the panels

Extra info

Buying PV panel in volume

My expectation is that the cost of Photovoltaic panels will come down over the next few years when the Chinese further ramp up production. You could potentially buy them direct from China and arrange your own container shipping. Import tariffs however are likely to increase the price significantly. Anti-dumping duties on solar panels from China can add something like 50% to the cost. Some Chinese manufacturers do what's called "trans-ship" to send the panels via eg Thailand to avoid the duties, but this increases shipping costs. Let's hope American companies invest in high volume production plants.

Note that even though PV panels are a significant cost, you will need to spend a similar amount or more on the electronics to go with them.

Rebates and tax credits

To help with the up-front capital costs there are some federal and some local state incentives. You can find what's available in your state at http://www.dsireusa.org/ .

The incentive offered often depends on where your solar panels and electronics was manufactured.

Selling electricity to the grid

It's nice to make your electricity meter run backwards and get a monthly check from the electricity company. Doing a fully connected and dependent grid connected system requires less electronics, but it means you are totally dependent on the power company. They determine how much they pay you for the electricity and your solar system will not operate during a power outage.

Even though it is more complex, my preference is for a solar system that can work off-grid.

Solar roof tiles

I care a lot about not messing up the look of the house. I want the roof to be completely uniform in appearance. That means if using solar on the roof that it has to cover the complete roof including all the way to the edges.

What would be nice is if someone comes up with solar roof tiles that

look nice...

http://www.latimes.com/business/la-fi-agenda-solar-20161031-story.html

Solar metal seam roofing is another possibility...

Solar film can be added to standard metal standing seam roofing strips.

http://www.inspirationgreen.com/integrated-solar.html

https://www.youtube.com/watch?v=NhRxxe_Tkgs

http://www.amazon.com/Unisolar-Flexible-Solar-Panel-Laminate/dp/B006EP6MCU

$200 per panel 19' long.

Flexible Thin Film Solar Panels. 128 watt

Solar Panel Laminate 24 volt

Unfortunately Unisolar has gone out of

business.

The negatives...

1) The efficiency of peal and stick is not as good as a dedicated panel.

2) They are only rated to last 20 years and will be a nightmare to replace as they are permanently glued to the metal of the roof.

3) Not much if any color choice.

4) They are not made in China so are more expensive.

It actually is not necessary for the entire roof to be solar as long as there is "dummy solar" that looks the same as the real solar. The dummy version can be used at the edges (where cutting and screw holes are needed) and on the north facing roof.

https://www.youtube.com/watch?v=NFPIDhbuOWU

PV and Water Piping

Instead of using Photo-Voltaic panels, routing water through or over the roof is another way of getting energy from the sun.

On the roof or free-standing?

Advantages of a free-standing unit in your yard...

1) As the roof is near the ground it is easy to replace faulty or worn out panels.

2) Appearance does not matter, ie it does not mess up the look of the house.

3) Can chose whatever panels are least expensive.

4) Easier to wash them (dirt hurts efficiency).

5) More panels can be added over time by building multiple cluster units.

6) Can be placed wherever there is a sunny spot in your yard.

7) Can be placed on sheds and other small structures.

8) Can be installed over septic tanks and sand filters etc.

Mainstream panel manufacturers

Suntech Power

Worlds largest producer of crystalline solar panels, with more than 10 million PV panels sold in over 80 different companies. To learn more about Suntech Power, click here.

SunPower

Produces the most efficient monocrystalline solar panels available. They also offer all black panels (no visible metal strips), inverters and monitors. For more information click here.

Transform Solar

Produces a revolutionary new thin monocrystalline panel that is heat resistant, even produces in conditions of partial shading, and is highly reliable. It also uses just a fraction of the silicon to produce the same high levels of efficiency. For more information click here.

JA Solar

The largest producer of monocrystalline

and polycrystalline solar cells, which it sells to other solar module

manufacturers. It also produces its own PV solar panels that it sells

primarily in China through its own solar development company Yangzhou

Engineering.

http://www.solar-facts-and-

https://yzxjgf.en.alibaba.com/

tinadai@xjsolarpv.com

Panel suppliers

Typically a different company (usually also in China) buys solar cells and makes them into solar panels/

https://www.alibaba.com/trade/search?fsb=y&IndexArea=product_en&CatId=&SearchText=solar+panel

PropSolar

BlueSun

Mono or Poly PV cells

http://energyinformative.org/best-solar-panel-monocrystalline-polycrystalline-thin-film/

Monocrystalline solar panels have traditionally had the highest efficiency rates since they are made out of the highest-grade silicon, but Polycrystalline has now almost caught up. Monocrystalline solar panels have been thought to live the longest but again things are changing. Nowadays it does not really matter which you choose, it is now about price per watt.

Monocrystalline

This is the oldest and most developed of the technologies. Monocrystalline panels as the name suggests are created from a single continuous crystal structure. A Monocrystalline panel can be identified from the solar cells which all appear as a single flat color with missing corners.

They are made through the Czochralski method where a silicon crystal ‘seed’ is placed in a vat of molten silicon. The seed is then slowly drawn up with the molten silicon forming a solid crystal structure around the seed known as an ingot. The ingot of solid crystal silicon that is formed is then finely sliced into what is known as a silicon wafer. This is then made into a cell. The Czochralski process results in large cylindrical ingots. Four sides are cut out of the ingots to make silicon wafers. A significant amount of the original silicon ends up as waste. It costs about 20% more to create solar cells with monocrystalline.

Polycrystalline

Polycrystalline or Multicrystalline are a newer technology and vary in the manufacturing process. Polycrystalline also start as a silicon crystal ‘seed’ placed in a vat of molten silicon. However, rather than draw the silicon crystal seed up as with Monocrystalline the vat of silicon is simply allowed to cool. This is what forms the distinctive edges and grains in the solar cell. Polycrystalline cells were previously thought to be inferior to Monocrystalline because they were slightly less efficient, however, because of the cheaper method by which they can be produced coupled with only slightly lower efficiencies they have become the dominant technology on the residential solar panels market. In November 2015 Trina Solar announced that it had produced a multi-crystalline cell with efficiency of 21.25%. This should allow them to produce polycrystalline modules with efficiencies between 18-20% a concept that was thought impossible as recently as 2013. Underpinning the new record for p-type multicrystalline solar cells has been the continued quality improvements of multicrystalline wafers that have helped pushed standard 60-cell multicrystalline panels from 240W to 260W in recent years. Polycrystalline are now very close to Monocrystalline cells in terms of efficiency.

Size

A common large format size is 1640*992*40 which is 5' 4-1/2" x 3' 3' x 1-1/2". Add 1/8" around panels.

A smaller common smaller size is 3'11" x 1' 9-3/8" x 1-1/2" (47" x 21.3" x 1.4").

Siting and Angle

Theoretically solar panels should face true south if you are in the northern hemisphere, or true north if you are in the southern hemisphere. As this is true south you are better off figuring this from Google maps rather than using a compass (which only shows magnetic north/south). If you have trees to the east but not the west, it may be better for you to aim your solar panels slightly to the west. Panels produce less power at higher temperatures so this can mean they work better earlier and later in the day.

Facing south west is likely to be best because you typically need more power in the afternoons and evening than in the mornings.

Ideally you would use a different angle in the winter compared with the summer, but this is a lot of hassle so I prefer to just stick to one fixed angle all year round.

The angle you want depends on the latitude where you live. I am in the Seattle area which has a latitude of about 47.6 degrees. The following calculations assume your latitude is between 25 and 50 degrees.

If you have a fixed angle mount then the calculation is...

Latitude x 0.76 + 3.1 degrees.

For me the

calculated fixed angle is 39.3 degrees.

If you are changing the angle between winter and summer then the

calculation is...

Summer: Latitude x 0.93 -

21 degrees.

Winter: Latitude x 0.875 + 19.2

degrees.

For me that makes summer 23.27 degrees

and winter 60.85 degrees.

In the "primarily heating required" climate where I live, energy is actually more useful in the winter. I therefore prefer to make the fixed angle a bit closer to the winter angle than the summer angle. My chosen angle is 45 degrees. Using 45 degrees also makes construction of the platform marginally easier.

For my Seattle latitude the optimum degree angles for each month

are...

Jan Feb Mar Apr

May Jun Jul Aug Sep

Oct Nov Dec

26 34

42 50

58 66 58

50 42 34

26 18

Grid-tied or off-line capable

It is far easier to do a grid-tied system, but it will not operate in a power outage. A grid-tied system detects the phase of the grid power and is able to synchronize to it. Crucially it stops generating power during a power-outage so it does not electrocute power company workers who are trying to repair the grid lines. Without this you need a fail safe transfer switch mechanism and that is hard to do if you also want to feed power into the grid in a non-power-outage case.

A grid-tied system is just a way to reduce your power utility bill.

Despite the difficulty, I expect electronics manufacturers to step up and produce the necessary equipment that is both affordable and meets the new electrical codes. Ideally I want a hybrid system that can work offline and yet can also feed electricity into the grid - This is currently difficult to do in an affordable way..

Inverters

Microinverters

These are for use with a grid-tied system.

Pros

Whether it's a leaf, dirt, or a cloudy day, obstructions happen. With microinverters, only the individual panel is affected, while the others keep performing to their fullest.

Cons

Difficult or impossible to connect to a battery array.

Does not work in a power cut as it always needs to sync with utility power.

String systems

Pros

Easier to connect to a battery array and use off-grid.

Cons

A string inverter system can only perform as well as its lowest-performing panel. If shade or a pile of leaves hinders one panel's performance, every other panel operates at the same diminished capacity.

More complicated.

Expensive big box.

Hybrid systems

These are currently very expensive.

Outback Power Radian GridZero

17825 59th Ave. NE, Suite B Arlington, WA 98223 United States

http://www.outbackpower.com/outback-products/make-the-power/radian-series-inverter-chargers

https://www.solaredge.com/us/solutions/residential#/

http://www.cleanenergyreviews.info/blog/2015/7/2/3-all-in-one-hybrid-inverters

China turnkey hybrid systems