Home Site Map - Steps - Roof and Attic -

Roof Framing

Roof design

Basic principles

The building science for my roof design is written up here .

Cathedral design

I want to maximize storage space in the roof and be able to easily move about, so it will be a cathedral 45 degree ceiling in the attic with a flat roof section in the middle. It is formed using 2x12s on 24" center. The roof is designed to allow for the fact that the max length of 2x12 you can buy is 20 feet (16'11" long is needed for the flat roof framing). For the 45 degree part of the roof only 12' long 2x12s are needed.

Roof Overhang

The overhang for the roof is not framed in wood. It is outside the thermal envelope of the house and as such needs to be made from materials that do not rot. I use CNC hotwire cut polystyrene. One block forms the cornice and one forms the 45 degree overhang with an integral rain gutter. The EPS blocks are added after the roof is framed (but before it is fully planked so there is still access from the attic).

Having a good sized overhang is nice because it keeps rain off the walls and windows. It is also an important architectural feature and makes the house look stylish. I use a 2'4" overhang all the way round (including on the gables).

Insulation

In my design the insulation goes on the actual angled wood roof rather than in the attic floor. This makes the attic a conditioned space that is fully usable just like any other room in the house. It also means you can have a viewing gallery all the way from the attic to the entrance door area. As you will see in my roof design as written up here the insulation goes on the outside of the wood roof planking.

Having the insulation on the outside means that the roof planking and roof beams are all visible from inside the house and form a great architectural feature.

Roof boarding

Traditional wisdom is to use plywood (CDX) of 5/8 thickness on a roof. Some people use 5/8 OSB as it is cheaper. I don't like plywood and I really I don't like OSB as it swells at the edges.

I prefer to use planking, ie real lumber. My choice is to use regular commodity 8 foot long 2x4s. This makes for a really strong roof structure and it is not that much more expensive than plywood.

You could use say 2x8s or even 2x12s, but 2x4s are less likely to split when they dry. They are also lighter to handle (and select when you buy). It's better to use 2-bys rather than 1-bys because that allows the roof trusses to be on a wider center, ie less roof beams required.

Use 3" screws to attach the 2x4s to the 2x12 beams. Screws also make it possible renew the lumber in many years time (although this should not be necessary as the wood is within the thermal envelope of the house so is kept warm and dry). Do not glue roof planking to rafters as it makes the planking difficult to replace. Accurate markings are used on the 2x4 planks to accurately hold the beams in the right locations.

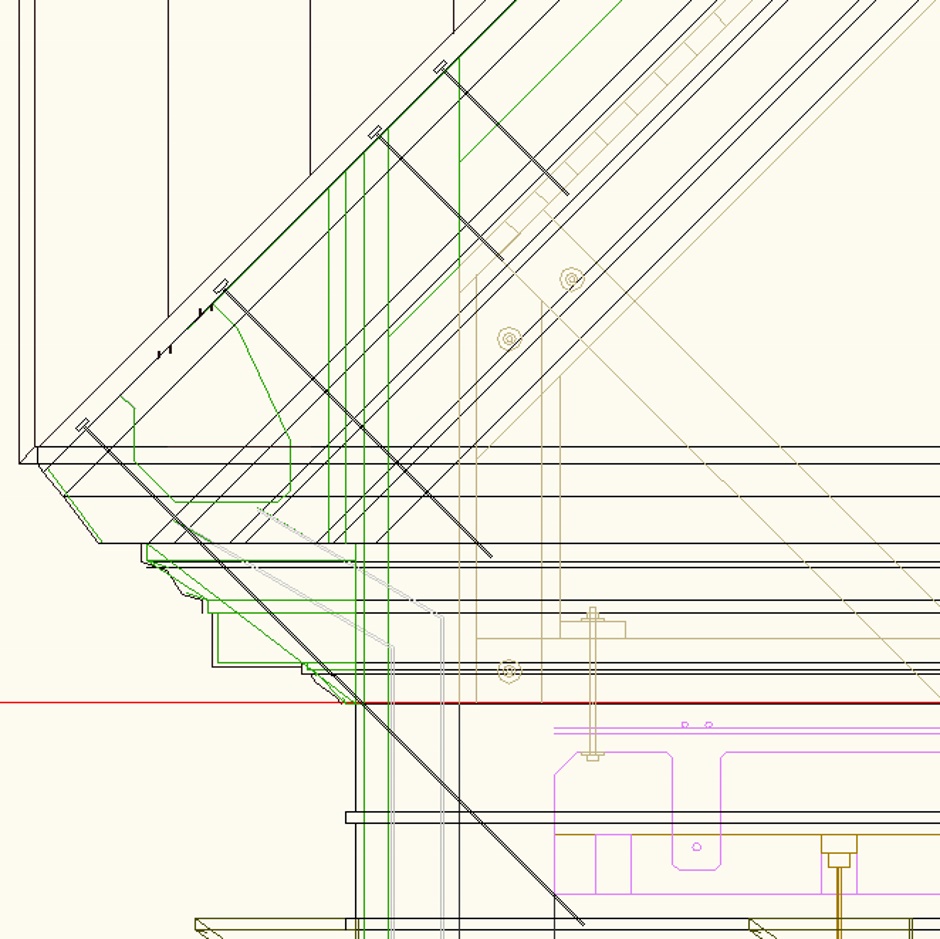

Roof drawings

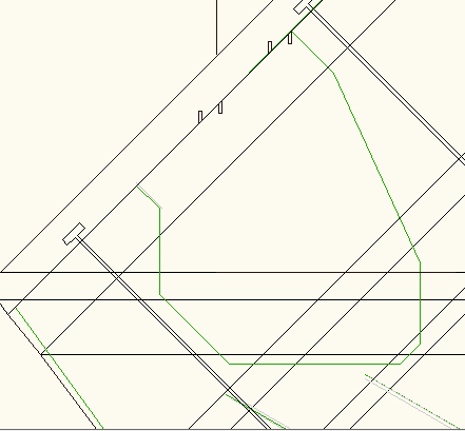

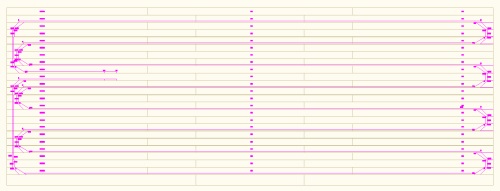

It is of course necessary to produce accurate drawings or you will not be able to mark and cut the various roof beams. The drawings are best done in AutoCAD.

Roof lumber

The roof beams are made from 2x12 lumber. Carefully select the lumber when you buy to ensure that it is totally straight and ideally without unsightly gouges. Personally I buy my lumber from Lowes and HomeDepot because they allow you to select yourself and they keep the lumber dry all the way from the drying kiln to the store shelf. You need to buy opportunistically depending on when they have a new batch on display. You won't want the dregs after someone else has picked through the batch. You may well find you have to examine ten pieces of lumber to find one that is acceptable.

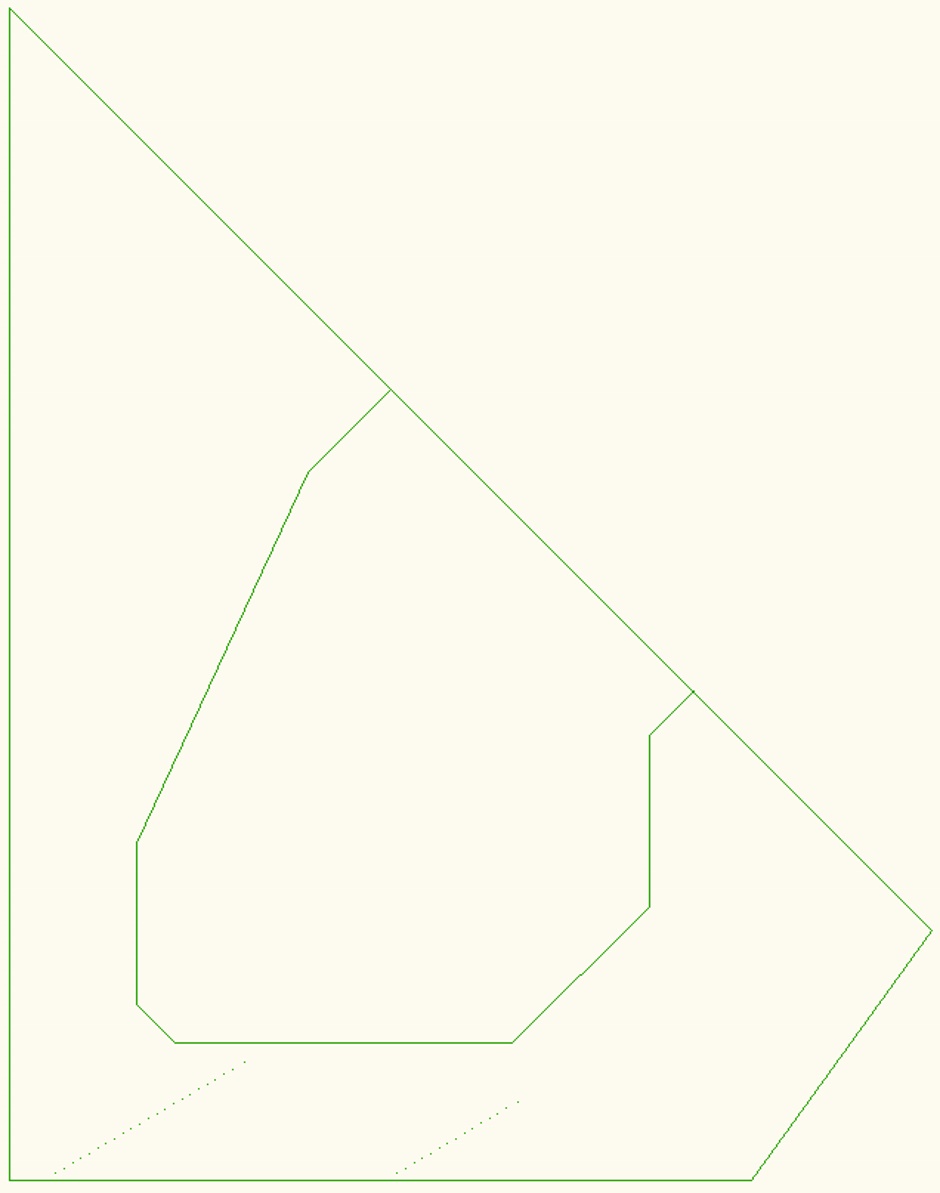

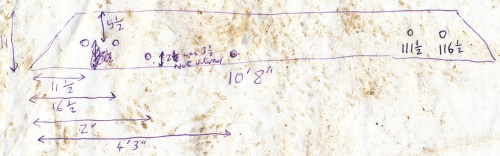

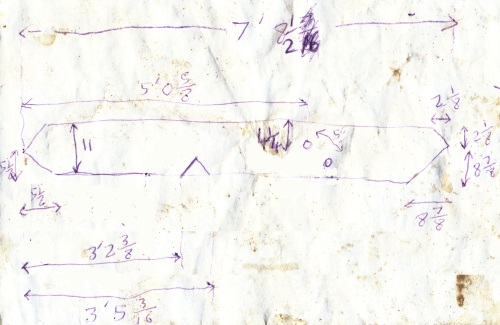

Triangle beam assemblies

The basic element of the roof are triangle beam assemblies that have the top of the triangle cut off to form the flat walkway along the ridge of the roof. The bottom of the triangle is the concrete attic floor. They are formed from one horizontal piece of 2x12 lumber and two 45 degree pieces at each end. The 45 degree pieces of 2x12 lumber are attached to the horizontal piece using half inch bolts (or half inch studding). These assemblies are typically positioned every 2 feet, although the spacing may vary at the gables and in the center of the building.

Heat extraction from roof

Given that the insulation is on top of the roof boarding it does no good putting PEX water piping in groves in the planking. Pipes could potentially be fitted to groves in the final layer of roof EPS but it has been decided that this is not worth doing.

Gutter

The water falls through the metal roof sheeting because holes are cut with metal sheers.

Safety

Working on a roof is dangerous. You need to use a fall harness .

The following is what was done on the evaluation building. The main house is different in the details and dimensions.

Horizontal beams for gables

Make horizontal beams

At this stage you only need 4 of these.

![]()

Fit gable horizontal beams

These go either side of the gable walls. They fit onto the 1/2" studding that is through the wall concrete.

Protect all roof lumber

After cutting all the lumber pieces, and before installing them, thoroughly paint them all with clear wood preserver.

Horizontal East West T beams

![]()

![]()

Horizontal North South beams every 2 foot

Flat roof sloping

Insulate gables

Also insulate at the ends under where the 45 degree planks will be...

Flat roof planking

Reference pieces of planking

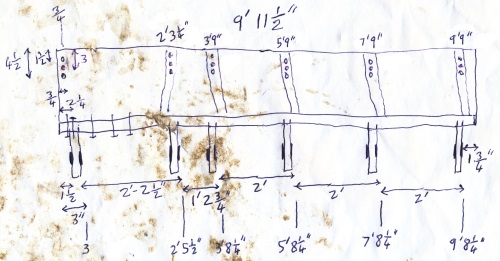

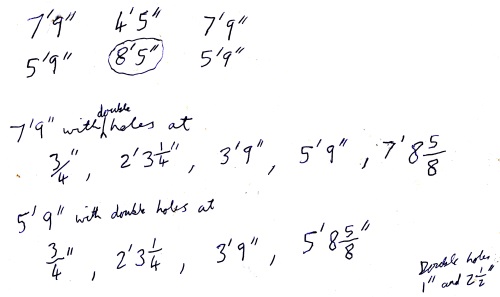

The first few pieces of 2x4 planking added also serve to hold all the beams accurately in the correct places. You should mark, cut, and drill these pieces before starting to assemble the roof framing.

![]()

Drill holes

The holes are at 1" and 2.5" from the edge. Most of the holes are drilled squarely using a pillar drill. The holes that are 3/8" from the end are drilled with the wood slightly raised at one end so the screws go more towards the center of the 1.5" wide beams.

Accurately mark planks with beam positions

Mark the planks on the underside and drill from the underside (using a pillar drill).

Extend the lines that mark the beam positions so they are visible up the edges.

Small expansion gap between planks

To avoid cumulative errors, put marks every 3-9/16". This leaves a 1/16" gap between the 2x4 planks. Use a pre-marked measuring stick to make it easier and quicker.

Pull beams to align with plank markings

45 degree beams every 2 foot

Make 45 degree pieces

There are actually two different types of 45 degree pieces. The ones that are for the gable overhangs (total of 8) do not need birds mouth notches whereas the ones that are internal to the building the rest on the concrete walls do require the notches.

Install angle pieces on the gable walls

Start by installing the 45 degree pieces on both sides of the horizontals attached to the concrete gable walls.

Fit metal tie straps

Use Simpson 3 foot long and 2 foot long straight metal plates. Drill half inch holes for the studding.

Roof edges

Make roof edges

Fit roof edges

45 degree roof planking

A few reference pieces of planking will already have been produced and installed. Now the rest need to be made and fitted.

Manufacture planks

They need to be cut and drilled before taking them up on the roof. Use clear wood preserver.

Roof water pipe grooves

Note that the roof design was changed to put the insulation on the outside and as such there is now no point in putting PEX pipe in the roof planking.

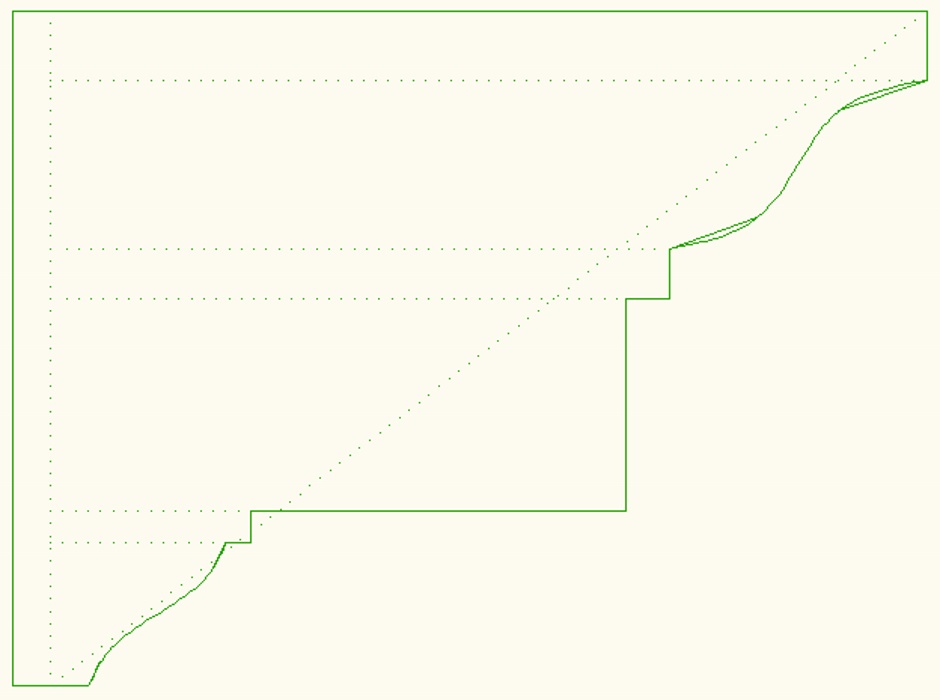

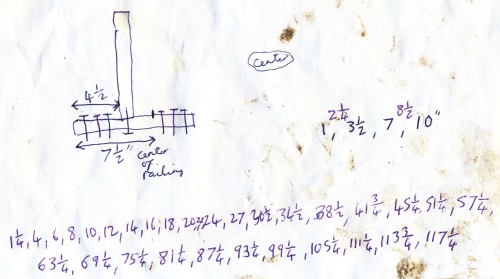

It is necessary to make a half inch (width and depth) groove in the top surface of the 2x4 planking to take the 1/2" PEX piping that is used for heat reclamation from the roof. The groove needs to curve 180 degrees backwards using a 10.5" diameter. It is best to route the pipe along the edge of every third 2x4 (3.5" x 3 = 10.5"). You can make two 5/8th inch deep cuts half inch from the edge of every third 2x4 to produce a channel for the pipe. In from the flat face go 1/16th deeper so the pipe is below the surface. The gap between 2x4s gives you extra width so you can subtract a 1/16" from the width.

At the roof ends it is necessary to cut a 5.5" wide, 5/8" deep cross channel to provide room for the PEX bend radius.

The pipe will be held in the grooves using small amount of duct tape and then the Grace Ice & Water Shield.

The pattern of pipes needs to take into account a 21" gap in the planking that forms an access hole for working on the roof. Access holes need to be about every 7-8 feet of linear roof. The PEX piping will have all needed to have been fitted before the access holes are filled with plain planks.

Here is the PEX pipe plan for the evaluation building roof...

The grooves in each numbered 2x4 plank to match the drawing are made using a circular saw set to a depth of 11/16". Make multiple close together cuts and break the bits in between out with a chisel.

Gap between planks

Before starting planking, mark the plank positions on the trusses. This truss marking will avoid cumulative errors from creeping in. The marking can be safely done once the trusses are in place because you can stand a step ladder on the attic floor between the trusses.

Planks alternate in length...

Grooves in the roof where the PEX pipe will be fitted...

Fitting the PEX piping is done later, but it is worth trying a short length to make sure it fits ok.

Picture of the site with the first few planks fitted...

And a few more...

When doing a larger roof, it is sensible to include a gap in the planking so that you can stand through the hole to work on the roof. You want the holes to be about every 8.5 feet (the width of 3 strips of Grace Ice and Water shield with overlaps). You will keep the hole until after the Grace Ice and Water shield has been fitted to the roof below the hole. You will then add the missing planks and vinyl drip edge and proceed with the Grace Ice and Water up the rest of the roof.

Capping and finishing details

The top capping 2x4 needs to be cut on the edge at 45 degrees so it fits.

Round the edge of the roof, fit vinyl drip edge. To form the corner join, cut the vinyl strip at 45 degrees. Use 1.25" long roof nails. Use nails about every 2".

Other notes

There will be cedar decking on top of the flat roof section

on top of the EPS insulation to make

it actually flat.