Home Site Map - Techniques - Structure -

Door and Window Bucking

![]() How to form wet concrete in ICF walls to make the openings for

windows and doors.

How to form wet concrete in ICF walls to make the openings for

windows and doors.

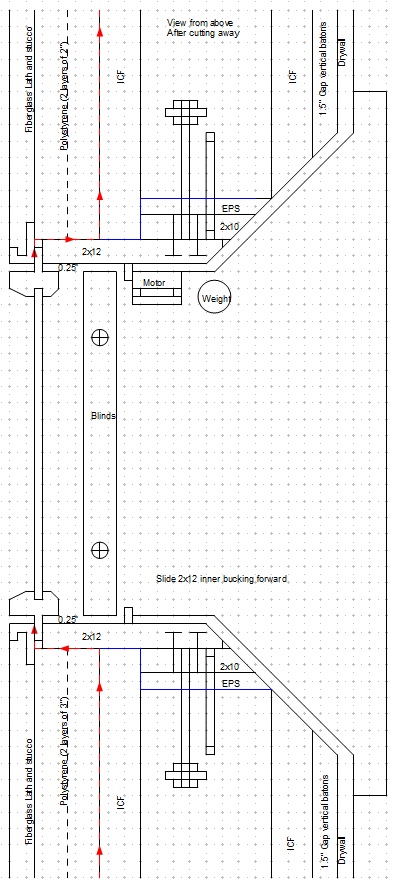

Cavity bucking and Sliding bucking

I use wooden bucking of my own design. The bucking uses 2-by lumber cut to 8" wide (or made 12" wide by gluing two pieces of 2-by lumber) in a rectangle to fit into the concrete cavity all the way round the opening (called the "cavity bucking"). A slightly smaller 2-by lumber rectangle fits within that and that is what the actual window attaches to (I call this the outer sliding buck). The bucks are made to the right window sizes. They have 2x4 bracing rectangles to keep them square and to stop flexing due to concrete pressure. The outer sliding bucks (made out of 10-1/2" 2-by) are positioned to the outside of the wall relative to the cavity bucks.

The design of my window bucking scheme allows the internal verticals of the window to be cut back after the concrete has set to considerably increase the angle of view through the windows, given that the walls are so thick. I use straight right angled bucking for the concrete pour and then cut away the EPS and some of the lumber after the concrete has hardened. The center concrete section will remain and will be what the window is anchored to. You need to have 1/2" steel studding (glued in place) from the cavity bucking into where the concrete will be so that the buck becomes a nice strongly attached window frame. This allows the bucking to be reduced in width after the concrete has set without the frame becoming loose.

It is necessary to be able to pump concrete through the window sill. To do this there need to be some holes in the bottom of both the cavity bucking and the sliding bucking. The holes need to be 3.5" wide. That is large enough to get the 3" concrete boom pump hose through. The holes should be about on a 6" pitch, ie about 2" of wood between each hole. In the center of the window sill there needs to be 4" of wood so that the internal buck bracing has something to push on.

Bucking for the concrete pour

The design

The red line in the drawing shows the join between the part of the bucking that stays within the wall (called the "cavity bucking") and the "sliding bucking" that is slid forward to become the protruding window mount.

The dimensions of the bucking for each window come from your house CAD drawings.

Make the cavity bucking

The first task is to use a table saw to cut some 2x10 lumber so that it is 8" wide. (You cannot use 2x8 lumber because that is only 7.5" wide.) Actually it is cut to be 7-15/16" so as to provide a 1/16" of clearance. Use this 8" cut lumber to form a rectangle who's inside dimensions are the same as the hole required in the ICF wall. Note that the wall hole is 3" wider and taller than the actual window (and that's not counting the extra 1/2" off the width and height that the window has). The 3" is twice the width of a 2-by.

If the lumber is slightly bowed, then make the bow towards the center of the opening because the inner sliding bucking will keep it pushed out.

Cut holes in the bottom of the cavity bucking. Start by finding the center. Measure 2" either side of the center and that is the start of the 4" holes on each side. This provides 4" of wood in the center for the internal bracing to push on. The 4" rectangular holes then repeat on 6" centers.

Drill holes in the lumber rectangle for the concrete anchoring studding. These holes are 2-3/4" in from the external edge. On the sides the studs are designed to be in the center of a 1' high ICF block (to avoid the webbing). That means they can be at 6", 1'6", 2'6" etc measured from the inside edge of the top lumber that forms the cavity bucking. Put holes on 1' centers. On the top and bottom put the holes 6" and 9" from the outside edge and then the double holes on 1' centers after that. The actual holes chosen (6" or 9") will depend on the relative location of the plastic web in the ICF blocks.

In the 1/2" holes will go 8" long threaded studs that protrude out into where the concrete will be. They have a washer held by two nuts near the end which will provide the anchor in the concrete. They will eventually be glued in place with PL-Premium adhesive when the ICF blocks are built up. For the moment we just want the holes.

There is no need to glue the rectangle because the anchor studding into the concrete will hold everything in place long term.

Cut some 1" thick EPS into strips that are 7-7/8" wide (just less than 8"). Glue this to just the left and right verticals of the cavity bucking. Use some duct tape to temporarily hold it in place while the glue is drying.

(It is good/required to keep a minimum of 2 foot of concrete wall at the corners and an ICF block on the long leg provides 2'1-3/8" of concrete, but that is assuming nothing inserted into the concrete cavity at the end.)

(Note that the pictures show 2" EPS being used, but I have now changed the design to be 1" EPS.)

For the 1/2" stud holes, drill though the EPS using the holes in the lumber to give the positions.

(Note that the picture shows cable ties but I have since decided that these are not necessary. Also the EPS on the top and bottom edges is not required.)

On the inside put 2" single sided tape over the 1/2" holes. This tape is a better choice than duct tape as it is thinner so less likely to get pulled off by the side force when the sliding bucking is fitted.

Make the sliding bucking

The sliding bucking (the inner bucking) is made out of 2x12 lumber with some 2x4 bracing. The inner dimension (eg 3' x 4') is the window "rough opening" size.

It is necessary to have nice square edges on the lumber, so cut both edges on a table saw so the final width is 10.5". On the verticals also put a bevel on the inside edge of the internal edge of half an inch (see drawing). This 45 degree surface is where the drywall will attach.

If the lumber is slightly warped then you want to arrange for the bow to be inwards. It will be pushed outwards by the 2x4 bracing. If there is a slight bend in the other dimension then make the window bucking bow to the outside of the house.

There is no need to choose nice lumber for use as the bottom of the rectangle as that will replaced later to form the final window sill (because of the concrete filling holes). Write on the outside faces of the lumber so you know which will be the inside faces, and also right left top bottom.

(The pictures do not show the concrete fill holes or the beveled edges on the verticals.)

Drill holes for the wood screws that hold the sliding bucking inside the cavity bucking. The holes are 3" in from the house internal edge. You don't need holes in the bottom piece of the rectangle as this will be replaced after the concrete pour. On the other three sides they will mainly be covered with drywall. On the verticals there should be a screw hole about 3" from the ends. On the top make the first holes 4.5" from the ends. Then put holes on the 1 foot points (again relative to the inside of the rectangle). Mark the hole positions on the outer faces of the wood.

Cut holes in the bottom of the cavity bucking. These will correspond with the holes in the cavity bucking. Start by finding the center. Measure 2" either side of the center and that is the start of the 4" holes on each side. This provides 4" of wood in the center for the internal bracing to push on. The 4" rectangular holes then repeat on 6" centers.

There is no need to glue the rectangle (the wood screws are enough).

To get the rectangle square, first determine the longest diagonal. Put wood screws at the longest corners and attach some garden wire between them across the longest diagonal. Put the screws on the external edge. Slightly offset from the corners so you can still measure the diagonal. Twist the wire to pull in the longest corners until the length of both diagonals is the same. Attach the diagonal lumber (first the end in the corner and then the end on the straight). When the wire is removed, check that the rectangle is still exactly square.

Use 2x4 lumber with 45 degree cuts on the end to brace the sliding bucking to be exactly square. Ideally the lengths need to be determined by looking at your house CAD drawings. The first diagonal piece goes 3.5" in from the external edge. Use clearance drilled holes to allow 3" wood screws to be used to attached the edgeways 2x4 bracing (leave 2" of wood not cleared).

Also use some additional 2x4s attached to the angled pieces to stop the sides and top/bottom from bowing in. Note that you should not screw these from the outside of the sliding bucking because you need to be able to easily remove them later. You will need a 2x4 spacer to attach to one of the pieces of diagonal bracing.

The following drawing shows the example for a window that is 3' wide and 4' high. To get the dimensions for different windows you need to look at the CAD drawings for your house and jot them down on a scrap of paper for cutting. Most windows are probably some integer number of feet, but doors are typically 6'8" high.

Here's an example of a larger sliding bucking...

Insert sliding bucking into cavity bucking

Even with the 1/8 clearance you may need a rubber mallet to gradually work the sliding bucking into the cavity bucking.

(The pictures show cable ties which I later decided are not needed, and they do not show the concrete fill holes. Also the EPS on the top and bottom is no longer required, and at the sides it should be 1" thick.)

Initially (ie for the concrete pour) the sliding bucking is about centered in the cavity bucking, ie hangs out about an equal distance on each side. Actually the setting needs to be accurately done such that there is 1-1/8" on the inside (not 1-1/2").

Use 2.5" wood screws through the pre-drilled holes to attached the sliding bucking and the cavity bucking.

Tips and tricks

Lumber can be a bit variable in its quality so getting nicely accurate bucking rectangles can be a challenge. Here are a few techniques that can help.

An offset clamp can be used to force the edges into alignment.

For warped lumber, more screws are likely to be necessary to keep it in line.

A laser can be shone along the edge to allow the edge to be straightened before the 45 degree bracing is screwed into position. The other edge will automatically be straightened because it is held the right distance apart by the bits of 2x4.

Adding legs and bracing

Details of how to do the ICF bracing are covered here . The bracing to hold the window bucking at the right height and accurately vertical is an enhanced version of the ICF bracing.

Particularly for very large bucking it is too much weight for the polystyrene of the ICF blocks to be able to support. It is necessary to have 2x4 legs down to the concrete slab to take the weight. This can be done by using joining pieces (made out of 2x6 lumber) to attach the verticals of the bucking to ICF bracing assemblies that are positioned both sides of the opening. They are attached on the inside of the building. Spaces of width 1.5" are needed. The ICF bracing is not screwed into the ICF webbing because the webbing is not likely to be in the position that corresponds to exactly each side of the opening.

The only difference from using regular ICF bracing assemblies is that it is necessary to build a mirror image version for the other side of the window opening. The 45 degree adjustable legs are used in the same way as when bracing ICF and can be adjusted to get the window bucking exactly vertical.

The 2x6 joining pieces have holes down each side that are 3/4" in from each edge. Put them about every 6" and 2" from the ends. The 2x6 goes from the bottom of the rough opening to 1.5" from the 1/2" bolt. The 2x6 can continue (typically not required) 5.5" from the bolt. The 2-by spacer is fitted 1.5" from the edge that joins to the vertical bracing.

The distance from the edge of the leg to the start of the 2x6 is determined primarily from your CAD drawings. On the drawings find the distance from the top of the concrete slab to the bottom of the window rough opening.

The bracing leg assembly is attached to the sliding bucking before the bucking is fitted to the building. The legs slot into the internal 2x4 ring that is nailed to the slab and the bucking assembly can be hauled by ropes into the vertical position. Thin spacers and/or wedges can be added or removed under the legs in the slot to adjust the vertical position. When hauling the bucking into position you will need the bucking assembly to be 3.5" higher than its final height in order to drop the cavity bucking (with its polystyrene surround) into the cavity of the ICF block below. You can do this by putting temporary spacer blocks under the legs (under the perpendicular 2x4s of the bracing)..

Wrap in polyethylene sheet

Wrap the complete assembly (including the actual window opening on the external face) with 6mil polyethylene sheet to keep the water out. Tape with Venture Tape to make sure it is waterproof. The sheet will go over the EPS on the cavity bucking. Hold it in place using double sided tape placed where the polystyrene of the ICF will be. On the inside it just needs to protrude about an inch beyond the bucking assembly.

The polyethylene over the bucking assembly will keep the wood dry (to avoid rot) and will also function as a temporary window. It is tempting to install the actual windows early, ahead of the concrete pour, but this is not advisable as they may get broken and the wall dimensions may change slightly after the concrete pour.

Build ICF blocks up to sill height

The bucking assembly is fitted once the ICF wall has been built up to window sill height.

The bottom of the window will be at a height that does not correspond with the top of an ICF block so you will need to cut the ICF block down to the right height. Your CAD drawings will tell you how much you need to cut away, but typically for a window with a rough opening that's an integer number of feet it will be 3" that needs to be cut away. Doors will be different, as will be bucking that holds multiple windows.

(My door is +1" so no ICF block needed, just glue on a 1" high strip of EPS and then the bracing lumber that will be put round the edges will take the force. For my south multi window the cut in is 6".)

You will need to cut away the top bit of ICF webbing. This can be done easily with a reciprocal saw. There will not be any concrete force above ICF blocks under the window opening so loosing the top bit of webbing is not a problem.

On the ICF that is up to window sill height, mark with a permanent marker the left and right edges of where the window will be by measuring from the corners of the building. Note that the opening in the ICF is 3" wider (and higher) than the window rough opening.

Once you know the lateral position of the bucking in the wall you will be able to drill the holes for the anchoring studs such that they avoid the plastic ICF webbing.

Gluing studding in place

During the construction of the ICF wall you will fit the 8.5" lengths of 1/2" studding that provide the anchor into the concrete. In the case of the top and bottom of the bucking you will choose which holes to use to avoid the ICF webbing.

You will need to cut away the polyethylene sheet round the holes.

The studs are glued into the cavity bucking using PL-Premium adhesive. Squirt it into the hole and then push in the stud.

Fit two nuts and a washer on the protruding end and lock them together using a couple of spanners.

Fit cavity bucking to sill height ICF

The cavity bucking part of the bucking assembly slots into the top of the ICF cavity. The cavity bucking should sit such that the bottom inner edge of the sliding bucking is flush with the cut top of the ICF block.

If it is a large heavy bucking assembly then you should put 2x4 legs on the inside of the house down to the concrete floor to help take the weight. Attach these to the verticals of the sliding bucking (not the bottom sill).

Use 2x4s with length adjusters (like used for the ICF bracing) at 45 degrees down to the floor to hold the bucking assembly exactly vertical. Attach these on the inside of the house from the sliding bucking verticals.

Build up the ICF blocks on either side

Build up more of the wall height with the ICF blocks. These will be cut to length such that the sides of the cavity bucking go into the ICF block cavity.

If necessary (typically not) remove ICF webbing to provide enough clearance for the cavity bucking with its EPS.

Add ICF blocks over the window

Assuming the window dimensions were designed to use the bottom of the ICF block above as the reference point then the blocks over the top will not need to be cut.

You need to avoid cutting any of the ICF webbing in the blocks on top of the window as they are needed to take the force of the wet concrete above.

With a spirit level and/or self leveling laser, check that the layer of ICF blocks above the window is completely level and straight.

Pump concrete into wall cavity

Use the holes in the bottom sill of the bucking assembly.

While concrete is setting

It takes a month for concrete to fully set, but at least during that month the polyethylene covered bucking will keep the wind and rain out of the building. If it's going to be a while until you get the windows and it's winter, you can even fit polystyrene sheeting to the sliding bucking to keep you warm.

Bucking cut away after concrete has set

Details

After the concrete has set it is ok to cut away the EPS and

lumber on the inside as per the diagram shown below on the left and

right (but not above and below).

Peel and stick flashing is used on the protruding part of the

sliding bucking.

On the outside are added two

2" thick sheets of EPS (overlapping seams).

On the outside, metal flashing is formed all the way round.

The section at the top also has a drip edge formed by bending over

the longer top metal edge.

On the inside, the 45 degree cut away left and right sides are

finished with drywall, as is the top above the window.

On the inside below the window a nice looking wooden window sill is

glued in place using

PL-Premium

adhesive .

View from above

View from the side

Butt to butt windows

Sometimes it is required to put two or more windows side by side or on top of each other without any wall between them. Some window manufacturers provide special joining mechanisms to allow for this. When purchasing my windows I found that using the manufacturer's special joining mechanism increased the quoted price considerably. I decided to treat the windows as separate windows and accept that there will be a 3" separation between the window.

The bucking is done by treating the 2 or more windows as one giant window. A gap between the windows is 3" and this allows the nail fins to not overlap. If there are two windows of height 4' on top of each other then the composite rough opening will be 8'3". When the windows are mounted in the giant sliding bucking the nail fins will have nothing to attach to at the join between the windows. A steel bar (3" x 1.5") can be mounted on the warm house side of the nail fins. You can tap the steel bar and use small screw bolts from the nail fins into the steel bar. On the outside side of the join you can use 2" thick EPS with a length of vinyl U section over the EPS. The EPS should prevent most of the thermal loss from the steel bar. For a 5' wide window, the steel bar will be 5'3" long. To mount the steel bar it is necessary to cut 1.5" deep (3" wide) notches into the sliding bucking to hold the ends of the bar.

Appearance

The following picture shows what a 6 foot wide by 4 foot high window looks like after the concrete has dried and the extra EPS and stucco has been applied. Above the window is a drip edge strip. The vinyl window frame is something like 1.5" wide round the actual glass. Over the EPS sheet is applied a stucco finish that looks very convincingly like regular house brick.

Waterproofing

The drawings show the relationship between the polyethylene sheet over the wall and the nail fin of the window.

It is also necessary to seal the join with self-stick waterproofing flashing tape. A suitable sealing tape is detailed here .

Window installation

There are three functions we need to achieve when mounting windows...

Securely attach the window so it does not fall out

Avoid air and water infiltration

Allow for expansion and contraction

The chosen window design (and the most common type) has a nail fin all the way round the outside. This attaches to some 2-by lumber that forms a rectangle that is half an inch wider and half an inch taller than the actual vinyl frame of the window. The windows are installed from the exterior.

If the bucking is properly rectangular with accurate right angles and straight sides then the window will have 1/4" shims all the way round the outside. Actually, the 1/4" shims will only be needed at the bottom and one on each side. The shims will hold the window in the right place while the nail fin is being attached to the lumber bucking.

At the bottom sill prior to installing the window you should put self adhesive flashing tape. Only extend into the sliding bucking by about an inch because you don't want it to extend past the window frame or else it would be visible. The aim of this tape is to catch any water that collects at the bottom and guide it out over the outside of the polyethylene sheet. Extend it up the sides about 6" and stretch it at the corners to make a nice waterproof shallow U. It can only be done along the bottom edge of the window because that is the only case where the polyethylene sheet is behind the nail fin. On the sides and at the top use some slightly compliant double sided tape or some draft excluder.

Ideally put a screw in every pre-punched hole in the nail fin, although it is just about acceptable to screw on every other hole. Use #8 pan head 2" stainless screws (not countersunk). Do not over tighten as you want the possibility of some slight movement.

For stucco, it is necessary to use a J strip to maintain the 1/4 gap all the way round the window. You do not want the stucco to come all the way to the vinyl frame or there might be expansion/contraction issues. The gap will be filled with silicon sealant. At the top, rather than a J strip, use a strip that also forms a drip edge to deflect water away from the window.

After the window is installed, tuck the polyethylene wall sheet over the nail fin on the sides and the top. Cut the polyethylene sheet on the sides and top so it is only half the nail fin width so there is still some nail fin for the self adhesive flashing to still to. Put self adhesive flashing tape over the nail fin on the sides and then the top edge.. The flashing tape should extend up the side if the frame by about an inch to increase the vinyl surface it is stuck to. Do not put any flashing tape on the bottom edge.

Use "Great Stuff Pro Window and Door Insulating Foam Sealant" from Dow to fill all the way round the 1/4 gap on the inside. This particular variant of Great Stuff has just the right amount of expansion. Prove about an inch of thickness rather than completely filling the gap space.

For the 1/4" gap on the outside use closed cell round flexible backer rod followed by high quality exterior grade silicone sealant. The backer rod should be pushed in as far as it will go. The sealant should be shaped to be concave so with the round backer rod on the other side it will be hourglass shaped.